Soft Magnetic Nanocrystalline Alloys: Materials and Models

Victorino Franco

Departamento de Física de la Materia Condensada, ICMSE-CSIC Universidad de Sevilla, P.O. Box 1065, 41080, Sevilla, Spain

Introduction

Magnetic materials permeate numerous daily activities in our lives.1 They are essential components of a diversity of products including hard drives that reliably store information on our computers, decorative magnets that keep the shopping list attached to the refrigerator door, electric bicycles that speed our commute to work, as well as wind turbines for conversion of wind energy to electrical power. While permanent magnets require materials that maintain their magnetization even under the influence of external stimuli, soft magnetic materials can easily change their magnetization when external conditions require it. Permanent magnets require the magnetization vs. field hysteresis loop, M(H), to be broad, with a large coercive field in order to allow energy to be stored in the material. In contrast, soft magnetic materials require a narrow hysteresis loop, which implies the use of small amounts of energy to magnetize the material. As the area of the loop is related to energy losses during the cyclic magnetization of the material, a low coercive field implies better energy efficiency of the final application in which the soft magnetic material is used.

In addition to saturation magnetization (Ms), the most relevant properties of soft magnetic materials are the coercive field (Hc) and the magnetic permeability (μr). Maximizing Ms and μr uses less material to achieve the same value of magnetic moment (Ms) and a larger response to the excitation field (μr). In contrast, optimized soft magnetic materials have the lowest possible value of Hc. From a practical point of view, large values of μr imply that permeability and susceptibility (χ) are interchangeable for the purpose of describing the properties of the material, expressed as μr = 1 + χ ≈ χ. In addition, large susceptibility requires additional attention when characterizing the magnetic material. The magnetic field sensed by the sample, the internal field Hi, is not directly the applied field Ha, but rather depends on the demagnetizing factor (N) of the sample: Hi = Ha – NM. If we disregard the difference between internal and applied fields and we consider that the apparent susceptibility of the sample (χa) associates magnetization and applied field (instead of relating magnetization and internal field, which stands for the intrinsic susceptibility of the material, χ) we obtain:

Therefore, for samples with large values of N made of materials with a large value of χ, the apparent susceptibility does not depend on the actual value of the susceptibility of the material, but only on the demagnetizing factor, as: χa ≈ 1/N (Equation 2).

Thus, the measurement is exclusively dependent on the shape of the sample. To avoid this artifact, geometries that minimize N, such as long wires magnetized along their axis, planar samples magnetized in plane, or toroids magnetized along the toroidal direction are best used. As a direct consequence of Equation 2, the internal field is cancelled, shielding the magnetic field from a spatial region. In fact, a cage made using a soft magnetic material with large susceptibility provides a path for the magnetic field, minimizing its value in the interior of the cage. This explains why mu-metal®, with relative permeability values on the order of 500,000, is used in this type of application.

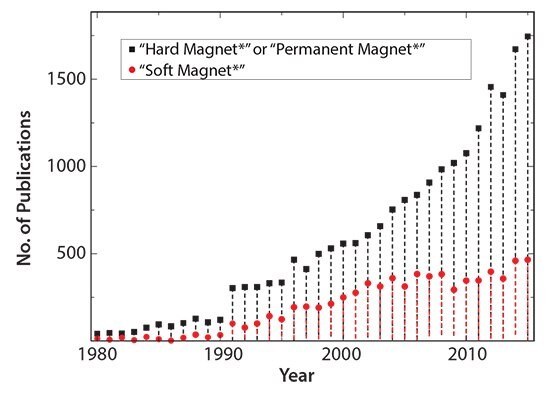

Scientific publications on soft magnets have steadily increased over the past decades. For example, the discovery of the alloy FINEMET® with its outstanding soft magnetic properties has made the field more attractive to researchers.2 A comparison between the number of papers published on soft magnets to those on hard, or permanent magnets (Figure 1), shows the latter field has been more active in recent years. The accelerating research on soft magnetic nanocrystalline materials in Asia is considered a major driver of growth in the field. This heightened interest has generated an increased demand for and consumption of electrical steel since 2008, promoting the installation of new transformers to improve grid reliability and reduce energy losses. The connection between energy efficiency and soft magnets will help to move soft magnetic nanocrystalline alloy research back into the forefront in the future.

This article provides a brief overview of soft magnetic nanocrystalline alloys. As indicated above, a main goal of optimizing these materials is to obtain the lowest possible coercivity. Here, we review the most important families of nanocrystalline soft magnets with a description of their typical properties and how their composition and processing allow the optimization of these properties. Finally, we present an outlook of potential future fields of interest.

Figure 1. Evolution of the number of publications appearing in Science Citation Index Expanded on soft magnetic materials and permanent magnets since 1980. The search string used for the search is provided in the labels.

Desired Properties

The dependence of coercivity on crystal size exhibits two different behavioral regimes. The traditional method of decreasing coercivity in soft magnetic materials has historically been to increase grain size because this decreases the amount of grain boundaries that act as pinning centers for the domain walls. By increasing grain size from 100 nm to 100 μm, it is possible to decrease Hc from ~10,000 A/m to values on the order of 1 A/m. The counter-example of this approach appeared with the emergence of amorphous and nanocrystalline materials. By decreasing grain size to values on the order of 10 nm or even making the solid amorphous, coercivity decreases to reach values comparable to those of very large crystals. Taking into account that an amorphous structure is, by definition, full of defects, the previous argument of decreasing coercivity with decreasing concentration of defects no longer holds true. This characteristic behavior can be explained with the Random Anisotropy Model (RAM) of Alben, Becker, and Chi3 and has been applied to nanocrystalline alloys by Herzer.4

Random Anisotropy Model: An Explanation Based on Analogies

A formal explanation of the RAM remains elusive for researchers more interested in material properties than in the development of physical models. However, understanding the physics behind the model can help in designing materials with the desired performance. We use several analogies taken from everyday life to grasp the concept of RAM. The message here is that the existence of very different length scales in the sample is responsible for the vanishing effective anisotropy of the amorphous and nanocrystalline alloys, which gives rise to extremely low coercivity values.

The first example takes us on a walk to a traditional monument found in many old cities, like Sevilla. Many of these ancient cities have patios with a floor made of numerous pebbles. When walking on top of these floors, those wearing high heels will typically have more difficulty walking than those wearing flat-soled shoes. The most reasonable explanation for this circumstance is that high heels have a typical size comparable to the pebbles and the gaps between them so they detect the discrete maximum and minimum heights of the floor. Flat shoes average the irregularities and allow us to walk more steadily because the heel is much longer than the pebbles and gaps.

Another example uses two refrigerator magnets with the same characteristics (ideally, two identical ones). Magnets of this type are fabricated using polymer-bonded ferromagnetic particles with a domain structure consisting of a set of stripes pointing outward and inward on one side, with the other side containing closure domains. The side with the closure domains is typically decorated and will not stick to the fridge. When one magnet is placed directly on top of the other with the same orientation (decorated sides facing the exterior), the magnets stick together. However when one magnet is slid perpendicular to the stripe domain, the upper magnet jumps as it moves along the attractive and repulsive regions with a periodicity corresponding to twice the domain width. As both the upper and lower magnets have the same characteristic length, i.e., the width of the domains, the system samples energy maxima and minima and they are detected macroscopically. This can be felt in our hands when trying to move the magnets, often producing a sound due to the abrupt attaching and detaching of the flexible laminae. However, if we rotate the upper magnet 90° with respect to the lower magnet, in a perpendicular orientation of the stripe domains of both laminae, the movement in any direction becomes smooth. It is not because the local maxima and minima have disappeared. There are still regions where equal poles face each other and therefore repel, as well as areas in which opposite poles lie on top of each other, creating attraction. The difference with respect to the previous situation is that any position of the upper magnet samples the same amount of attractive and repelling areas. The periodicity of the lower magnet remains the width of the domains, while the periodicity of the upper magnet turns to the length of the magnet. As one is much larger than the other, we cannot macroscopically detect the local energy difference and the magnets displace smoothly, similar to the flat-soled shoes on the pebbled patio.

A Simple Model for Nanocrystalline Alloys

Nanocrystalline alloys also can be modeled in a simple fashion as an ensemble of single domain nanoparticles (shown as squares in Figure 2A) with a typical grain size of 10 nm and with randomly oriented easy axes. Even if Fe-based nanocrystals have cubic magnetocrystalline anisotropy, we consider uniaxial anisotropy in the current model. We will show that the effective anisotropy is almost averaged to zero, thus this assumption of symmetry does not affect our conclusion. Consider the case in which the domain size (connected to the magnetic correlation length and marked as a thick white square in Figure 2B) is comparable to the structural correlation length (the grain size in Figure 2A). Assuming we have a domain in which the magnetization is oriented in the horizontal direction inside the white square, we color code the anisotropy energy of the different crystals from blue (minimal anisotropy energy) to red (maximal anisotropy energy). It is easy to see in the figure that it is not equivalent to displace this domain in all directions, since in some cases we gain blue squares (when moving to the right), while we don’t notice a remarkable difference in red or blue when moving up because there is anisotropy in the displacement of the domain. When we progressively decrease grain size while keeping the domain size constant, differences in energy will become gradually smaller when we move the domain in any direction, becoming negligible below a certain grain size. Each grain has its own anisotropy energy, but the system as a whole does not present anisotropy. In order to perform this simulation more quantitatively, we create different grids using different ratios of grain size to domain size and place the correlated domain at all positions in the grid, calculating the total value of energy in each position and the difference between maximal and minimal energy values for each of the grids. When we plot the difference in energy as a function of the number of particles inside each domain, N, we clearly observe a decreasing trend that can be fit to a 1 /√Ν law. Taking into account, for this model, anisotropy is a function of the difference in energy for each position of the domain inside the grid, we observe that the effective anisotropy, K*, corresponds to K* = K /√Ν, where K is the anisotropy of the crystals. This is the same result formally obtained from the RAM and originates from the difference between the magnetic correlation length and the structural correlation length. As a consequence of this discussion, when particle size decreases noticeably below the exchange correlation length, the effective anisotropy decreases toward zero and makes coercivity practically null.

This simplistic explanation, while keeping the essence of the phenomenology, was improved by also considering nanocrystalline alloys are not only formed by the nanocrystals, but they are two-phase systems in which the nanocrystals are embedded in a residual amorphous matrix, which is also ferromagnetic. More sophisticated models for multiphase materials have been developed5,6 that also include the contributions of magnetoelastic energy.

Figure 2. A) Set of Lc-sized particles with randomly oriented uniaxial anisotropy. B) Color-coded energy of such crystals if their magnetization is horizontal, showing one particular size of the magnetic correlation length Lm. C) Relative differences in energy of the correlated region when placed in all different areas of the ensemble, as a function of the number of crystals inside the correlated region (by altering the Lm/Lc ratio); inset: logarithmic plot and linear fit to the data, showing 1 /√Ν dependence.

Soft Magnetic Nanocrystalline Alloys

As indicated in the previous section, obtaining materials in which the exchange correlation length is much larger than the structural correlation length will lead to effective magnetic anisotropies that are negligible when compared to the magnetocrystalline anisotropy of the bulk material. In practice, this can be achieved by controlled crystallization of a precursor amorphous alloy.

A major breakthrough in this research field took place with the discovery of the FINEMET® alloy by Yoshizawa, Oguma and Yamaguchi in 1988.2 This alloy is formed from Fe, Si, and B, with small additions of Cu and Nb, and has a typical alloy composition of Fe73.5Si13.5B9Cu1Nb3. The alloy is usually fabricated using rapid solidification techniques such as melt spinning in order to obtain an amorphous precursor with the desired composition. At this stage of the fabrication process, the role of B is to increase the glassforming ability of the precursor alloy. Subsequently, the obtained ribbons are submitted to controlled annealing, typically 1 h at temperatures on the order of 500 °C in order to obtain the desired microstructure of α-FeSi nanocrystals with a typical grain size of 10 nm embedded in a residual ferromagnetic amorphous matrix. The role of Cu is to favor the nucleation of the nanocrystals via segregation either prior to or at the early stages of nanocrystallization. Conversely, the slow diffusing Nb accumulates at the boundaries of the emerging nanocrystals and hinders grain growth.

This special microstructure creates the optimal soft magnetic properties found in this type of alloy; the nanocrystals couple magnetically through the amorphous ferromagnetic matrix in which they are embedded, making the magnetic correlation length much larger than the size of the nanocrystals and averaging the magnetocrystalline anisotropy down to zero. Nevertheless, magnetocrystalline anisotropy is not the only source of coercivity. Magnetoelastic anisotropy also plays an important role. However, the different sign of the saturation magnetostriction constant of the two ferromagnetic phases (negative for the nanocrystals, positive for the amorphous matrix) means that, for a proper amount of the crystalline fraction, this source of anisotropy also vanishes. This makes FINEMET one of the softest materials known to date, with coercivities under 1 A/m. Compositional variations of the alloy produce slightly different Si content in the nanocrystals, altering the value of their magnetostriction constant. This modifies the overall magnetic anisotropy and alters either the optimal crystalline fraction to minimize coercivity, or prevents the overall magnetostriction from vanishing.7

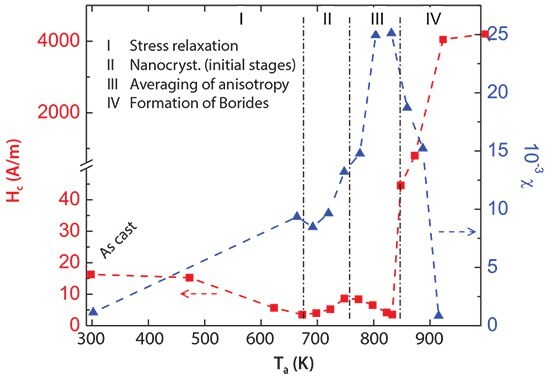

The dependence of coercivity on annealing temperature, i.e., changing microstructure, is illustrated in Figure 3.8 As cast, the amorphous alloy is considered soft for most applications. Annealing at temperatures below the first crystallization stage produces a decrease of coercivity due to stress relaxation processes, diminishing magnetoelastic anisotropy. The appearance of the first nanocrystals increases coercivity by acting as pinning centers for the domain walls and by inducing new stresses in the sample. Increasing annealing temperature further increases the crystalline volume fraction. When the fraction is large enough, the nanocrystals are magnetically coupled through the ferromagnetic amorphous matrix, averaging the magnetocrystalline anisotropy according to the random anisotropy model extended to two-phase systems.5,6 Finally, the onset of the second crystallization stage, with the precipitation of highly anisotropic iron boride type phases, increases coercivity to such an extent the material is of no use as a soft magnet.

Figure 3. Annealing temperature dependence of room temperature coercivity and initial susceptibility of Fe76Cu1Nb3Si10.5B9.5 alloy.

Fabrication and Processing

The most common methods for obtaining nanocrystalline microstructure include either conventional annealing in a furnace or Joule-heating/flash annealing, i.e., passing a current through a sample in order to heat it in a controlled fashion. The latter method has been proven useful in reducing the brittleness of the nanocrystalline samples9 and is also combined with the simultaneous application of mechanical stress.10 Processing the alloy under the combined effect of temperature and magnetic field is also useful for inducing anisotropy in the alloys and, therefore, controlling the shape of the hysteresis loop, making them more appropriate for certain applications.11–13

Although there have been attempts to produce these ultra-soft nanocrystalline alloys using mechanical alloying of pure elemental powders, the coercivity of these powders is considerably higher than that obtained for ribbon-shaped samples.14 The increase in magnetoelastic anisotropy due to the additional microstrains and the reduced mobility of domain walls as a result of the size of the powder particles are the main causes of the increased coercivity. It is also important to consider the difficulties in incorporating B into the alloy, despite starting from amorphous or crystalline B powders.15

Compositional Effects

In recent years, there have been numerous studies on the influence of composition on the soft magnetic properties of amorphous and nanocrystalline alloys. Due to the necessary brevity of this paper, the reader is referred to the literature for more comprehensive reviews.16,17 In addition to the FINEMET® alloy and its variations already mentioned in this paper, the three most relevant families of nanocrystalline alloys for soft magnetic applications are NANOPERM®, HITPERM, and NANOMET®. NANOPERM alloys have a typical composition of Fe88Zr7B4Cu.18,19 The larger Fe content and the lesser amount of B increases its saturation magnetization with respect to FINEMET alloys. The nanocrystalline phase consists in α-Fe, in contrast to the FINEMET alloy which also contained Si in the nanocrystals. This has made these alloys a preferred system for the study of the nanocrystallization process via Mossbauer spectroscopy.20

HITPERM alloys were designed as high-temperature soft magnetic materials.21 Their original composition was Fe44Co44Zr7B4Cu, in which Co serves two purposes. On one hand, it helps to maximize the magnetic moment, as Fe-Co alloys are at the top of the Slater-Pauling curve. On the other hand, Co increases the Curie temperature of both the residual amorphous phase and the nanocrystals (which are α-FeCo and α’-FeCo) and allows the operation of HITPERM alloys at much larger temperatures than the other families. But for high temperature applications, the challenge is not only connected to the Curie temperature of the phases, but since we are dealing with metastable materials, we also have to take into account the temperature at which microstructural transformation will take place. This family of alloys fulfills both requirements.

The latest addition to the families of soft magnetic nanocrystalline alloys is the NANOMET alloy, with typical composition Fe83.3–84.3Si4B8P3–4Cu0.7.22 NANOMET was developed to increase the saturation magnetization and minimize material cost by reducing or eliminating the metallic additions of Nb, Zr, Mo, and Cu which were usually required in the alloy families in order to achieve the nanocrystalline microstructure. These nanocrystalline alloys show high saturation magnetization, comparable to the commercial Fe-Si crystalline soft magnetic alloys, and low coercivity.

Regardless of the alloy family, nanocrystalline soft magnets must be optimized for specific operating conditions. A material with good performance at room temperature will most likely not be suitable for cryogenic applications. Cryogenic application studies of the compositional effects in the (Fe,Si,Al)NbBCu alloy series show that proper selection of the Fe:Si:Al ratio allows for the optimal combination of high saturation magnetization, low coercivity, and large electrical resistivity at liquid nitrogen temperatures.23 In another recent example, the Curie temperature of amorphous and nanocrystalline alloys was tuned by compositional variation of the Co:Ni ratio in the Fe882xCoxNixZr7B4Cu1 alloy series with the aim of analyzing the potential of Fe-based amorphous alloys for room temperature magnetic refrigeration.24 The Fe88–2xCoxNixZr7B4Cu1 alloy series exhibits the largest refrigerant capacity (RC) of Fe-based amorphous alloys found to date, while still keeping one of the largest magnetic entropy changes among Fe-based amorphous alloys. For magnetic refrigeration, it appears that nanocrystalline Fe-based25 and Ni-based26 alloys are not suitable and amorphous alloys are preferred, since the magnetic entropy change peak of the two-phase nanocrystalline alloys is split between the magnetic phase transition of the amorphous phase and that of the nanocrystals, decreasing its total magnitude.27

In addition to their use as soft magnets, ultra-soft magnetic materials can be combined with other materials for the development of exchangecoupled nanocomposite permanent magnets, in which a nanoscale soft magnetic phase is added into a hard magnetic phase matrix, increasing the energy density of the composite due to interphase exchange coupling.28

Nevertheless, the scientific interest in soft magnetic nanocrystalline alloys is not only driven by their technological applications and potential to increase energy efficiency. Their two-phase nature, with magnetic phases with different Curie temperatures, makes them a good testing ground for conducting fundamental studies in magnetism. Soft magnetic nanocrystalline alloys have been used to study the superparamagnetism of nanocrystals embedded in the matrix29 in order to develop models of the dipolar interactions between superparamagnetic nanoparticles30–33 or to propose procedures for the determination of critical exponents of multiphase magnetic systems.26

Conclusions and Outlook

Nanocrystalline alloys are among the softest magnetic materials known to science, and different alloy families have been optimized for unique applications and operating conditions. In addition to compositional effects that will affect intrinsic magnetic properties, the use of different processing methods enables the optimization of extrinsic properties such as coercivity.

The physical reason for the extremely low values of magnetic anisotropy and coercive field can be explained using the random anisotropy model: the two characteristic length scales of nanocrystalline alloys (grain size and magnetic correlation length) are very different, and anisotropy cannot be detected macroscopically, even if each nanocrystal is anisotropic.

Soft magnets are currently used in a variety of applications, ranging from energy conversion to sensors. Remaining challenges in the development of soft magnetic nanocrystalline alloys include the optimization of material properties for specific applications and the enhancement of their usability by decreasing brittleness and increasing thermal stability of the metastable phases. These goals can be achieved by a combination of compositional changes and appropriate processing of the alloys. Tuning the hysteresis loops by processing the materials under the simultaneous influence of magnetic field, stress, and temperature is a promising route to broadening the applications of nanocrystalline soft magnets. In addition, the design of exchange-coupled hard-soft magnetic nanocomposites is an area of significant interest in which ultrasoft nanocrystalline alloys may play a role. Moreover, the interest in soft nanocrystalline alloys is not limited to technological applications as these materials are also a good testing ground for developing fundamental models of multiphase magnetic materials.

Acknowledgments

This work was supported by MINECO and EU FEDER (project MAT2016-77265-R) and the PAI of the Regional Government of Andalucia.

References

Para continuar lendo, faça login ou crie uma conta.

Ainda não tem uma conta?