906913

TissueFab® bioink

Alg(Gel)ma -Vis/525 nm

Synonym(s):

Alginate, Bioink, GelMA-Alginate bioink, Gelatin methacrylamide, Gelatin methacrylate, Gelatin methacryloyl, Sodium alginate

About This Item

Recommended Products

description

suitable for 3D bioprinting applications

form

gel form (Viscous)

impurities

≤5 CFU/g Bioburden (Fungal)

≤5 CFU/g Bioburden (Total Aerobic)

color

colorless to pale yellow

pH

6.5-7.5

application(s)

3D bioprinting

storage temp.

2-8°C

Looking for similar products? Visit Product Comparison Guide

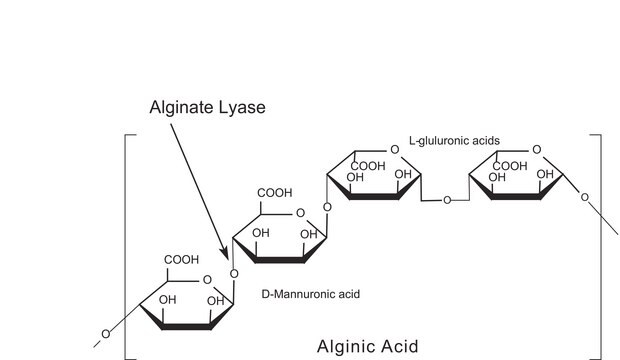

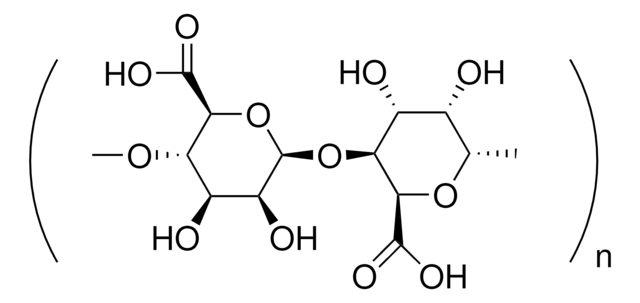

General description

Application

Packaging

Legal Information

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Skin Sens. 1 - STOT RE 2

Target Organs

Liver,Upper respiratory tract

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

It looks like we've run into a problem, but you can still download Certificates of Analysis from our Documents section.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service