High Crystalline, Solution-Processable Organic Field-Effect Transistors

Zhenfei He, Ming Chen, Paddy Kwok Leung Chan*

Mechanical Engineering Department, The University of Hong Kong, Hong Kong

Material Matters™, 2021, 16.3 | Material Matters™ Publications

Background and Introduction

Flexible transistors are the building blocks of next-generation soft electronics. Among all the reported material systems that can be fabricated by researchers, such as circuits, biosensors, stretchable displays, and others,1–5 small molecular weight organic semiconductors are among the most promising candidates for flexible transistor applications. For these small molecular weight organic semiconductors, the semiconductor forming the conductive channel dominates the device performance. Unlike inorganic counterparts like silicon or metal dichalcogenides with strong intermolecular bonding, these small molecules, although they can be packed exceptionally well under certain conditions, are usually held together by the weak van der Waals force only. As a result, the organic semiconductors in thin-film structures have better flexibility than inorganic semiconductors. The drawback, however, is the weaker carrier transport efficiency. Other than flexibility, another significant advantage of organic semiconductors is their tunability. Chemical or electrical properties like π-π stacking,6 responsivity to light with different wavelengths,7,8 and solubility in solvents9 can be adjusted by modifying the structure of the organic molecules or adding extra functional groups. As a result, one can tailor-make the molecules they want for specific applications, bringing organic transistors to a much broader spectrum of applications.

To date, thermal evaporation and solution processing dominate the fabrication of thin-film small molecule organic field-effect transistors (OFETs). As one of the commonly adapted vapor phase depositions, thermal evaporation is very suitable for large-area processing. However, thermal evaporated organic thin films typically have a polycrystalline structure with randomly orientated grains in varied sizes. density

The distribution of grains varies significantly among devices even when on the same substrate. The presence of the grain boundaries and the grain misalignment reduces the carrier mobility of the OFETs. Solution processing includes different methods like spin coating and ink-jet printing each with advantages and disadvantages. Spin coating is a fast technique and excellent for testing the intrinsic transport properties of the thin film; however, uniformity and compatibility with patterning can be a concern. Direct patterning is straightforward in ink-jet printing. However, similar to thermal evaporation, the weak control of the grain orientations is a common disadvantage of both approaches.

To address the orientation problem and guide the molecules, researchers developed a low-speed solution shearing method using the meniscus line to guide the deposition of organic molecules. In this method, the organic molecules “line up” at the meniscus before deposition onto the substrate. As a result, the crystal grows gradually in a direction parallel to the meniscus line and the size of the crystals is orders of magnitude larger than that developed by spin coating or ink-jet printing. Herein, we discuss a solution shearing method to achieve high-performance OFETs and their resulting performance.

Causes of Variations Among Devices

Device-to-device variation and reproducibility are crucial bottlenecks in the development of OFETs. Due to the quality of the organic thin film, the metal-organic interface or dielectric-organic interfaces are susceptible to processing parameters like deposition rate, deposition environment, or substrate surface quality. Thus, even when materials and fabrication equipment remain the same, the performance of OFETs from different groups can still vary significantly. Standardized substrates with the same quality predeveloped dielectric and electrodes on it are highly desired (Product Number FIPMS176, FIPMS148, FIPMS223, FIPMS175). The bottom gate, bottom contact (coplanar) OFETs can be finished by spin-coating or blade-coating the active layer directly onto the substrate. It is important to note that metal deposition onto organic semiconductors can be a rather sensitive process. Unlike the bottom contact devices, the quality of the metal-organic interface in the top contact OFETs strongly depends on the penetration depth of the metal atoms in the organic thin film. This penetration depth is related to the thickness of the semiconductor, the deposition rate, the packing density of the organic thin-film, as well as other factors. The effect of metal atom penetration is particularly critical when the bottom semiconductor layer is only a monolayer or a few layers thick. Although the coplanar structure OFETs may suffer from higher contact resistance, it does not have the same penetration depth issue as the staggered OFETs.

Different Structures of Solution Shearing OFETs

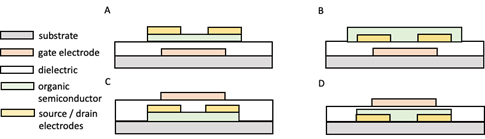

A schematic diagram of OFETs with the bottom gate top and bottom contact configuration is shown in Figures 1A and B, respectively. In the bottom gate configuration, the active layers are coated on the surface of the dielectrics, which play a vital role in device performance. The bottom gate structure is commonly adopted because a uniform, smooth substrate is favourable for semiconductor growth. A silicon substrate (Si) with silicon dioxide (SiO2) provides a good substrate for semiconductor thin film growth,10–14 with a mobility exceeding 10 cm2V-1s-1 can be achieved in a Si/SiO2 substrate-based OFET. To further improve the crystallinity of solution sheared organic thin films, several modifications to the application process are possible, such as a micropillar patterned blade to induce the recirculation of the solution,15 screen printing with polymer banks,16 blending solvents with induced Marangoni flow,13 or use of ion liquid hosted in porous anodized aluminium oxide as a substrate.17 The effect of the dielectric/semiconductor interface on the OFET is a popular research direction towards higher performance OFETs.

Figure 1.The four standard structures of OFET. A) Bottom gate top contact. B) Bottom gate bottom contact. C) Top gate top contact, and D) Top gate bottom contact. (A) and (D) are also known as staggered structures, while (B) and (C) are known as coplanar structures.

Other than improving carrier mobility, recent advances in solution sheared OFETs also include optimizing the operating voltage. A lower operating voltage can be beneficial for portable or wearable applications. Kitahara et al. reported a meniscus-controlled printing approach in which organic semiconductor thin films are blade coated on the surface of CYTOPTM with negligible traps, and realizing a subthreshold swing (SS) of 63 mV dec-1. This reveals the extremely sharp switching property of a transistor.18 A small SS value implies the device can be switched from off-state to on-state with a low voltage supply. A dielectric with high dielectric constants is also commonly used to reduce the operating voltages of the OFETs and suppress the short channel effect.12,19 Size miniaturization is essential on the path towards high-frequency operation.12,20 One drawback of the bottom gate top contact (BGTC) structure is the potential for thermal damage to the organic semiconductor during electrode deposition. The bottom gate bottom contact (BGBC, Figure 1B) structure can eliminate this potential damage and achieve highly reproducible results.21 Thus, this structure is very suitable for the quick screening of the intrinsic semiconductor properties without worrying about the device variation induced by the source and drain electrodes.

Besides the bottom gate configuration, the top gate (TG) structure (Figure 1C–D) is highly desired for independent gate control and adapted for driving circuits in a display application. In this structure, the dielectric insulator can also serve as the encapsulation layer to protect the channel from the surrounding environment. However, the compatibility of the dielectric layer deposition and the bottom organic thin film needs to be adjusted for this configuration. The processing temperature or the solvent used to develop the dielectric materials also need to induce a negligible effect on the organic semiconductor channel.22,23

State of the Art Performance of Solution Shearing Devices

In the operation of the OFETs, one indicator of device quality is operating frequency. The cutoff frequency (fT) of OFET is the frequency at which the transistor loses the amplifier ability. The cut off frequency is given as,24

where μeff is the effective mobility, VG is the applied gate voltage, Vth is the threshold voltage, L is the channel length, and LC is the contact length. As shown in the equation, a short channel and high effective mobility would be beneficial to achieve fast-speed operation. Borchert et al. and Yamamura et al. fabricated a transistor operating at 21 MHz25 and 29 MHz26, respectively, by using a short channel down to a few micrometers or even sub micrometers, based on 2,9-diphenyl-dinaphtho-[2,3-b:2’,3’-f]thieno[3,2-b]thiophene (DPh-DNTT) and 3,11-dioctyldinaphtho[2,3-d:2’,3’-d’]benzo[1,2-b:4,5-b’]dithiophene (C8-DNBDT-NW). For mobility, Peng et al. demonstrated a highly crystalline monolayer 2,9-didecyl-dinaphtho[2,3-b:2′,3′-f]thieno[3,2-b]thiophene (C10-DNTT) OFET with the mobility of 10.4 cm2V-1s-1 by dual solution shearing method (Figure 2A).27 Kumagai et al. used meniscus guided coating to fabricate a 4-inch wafer size 3,11-dinonyldinaphtho[2,3-d:2′,3′-d’]benzo[1,2-b:4,5-b’]dithiophene (C9–DNBDT–NW) single crystal by continuous edge casting method (Figure 2B).28 The OFETs showed high reproducibility with the mobility of 10 cm2V-1s-1 and an on-off ratio in the order of 10.7 Besides blade coating, a water-surface drag coating method, as illustrated in Figure 2C, has also been employed to develop a single-crystal thin film of 2,8-difluoro-5,11-bis(triethylsilylethynyl)anthradithiophene (Dif-TES-ADT).29 In this method, the organic molecules spread with the help of water surface tension, keeping them free from external force and enabling self-assembly into a highly crystalline film. The mobility of Dif-TES-ADT/polymer polystyrene (PS) blended OFET devices showed 5 times improvement compared with the blade-coating method and exhibited mobility of 10.1 cm2V-1s-1.

Figure 2.Shearing methods for high crystalline film deposition. A) Dual solution shearing method. Multilayer crystals with different orientations were formed at the 1st shearing. At the 2nd shearing, the upper layers were dissolved because of weak interlayer adhesion, while the bottom monolayer crystal was dissolved slowly and recrystallize due to strong adhesion to the substrate, leaving the high-crystalline monolayer. Reprinted with permission from reference 27, copyright 2017 Wiley. B) Continuous edge casting method. Crystal nanosheet was formed at the vapor-liquid interface of the meniscus line, where the solution is supersaturated because of solvent evaporation. The nanosheet was laminated on the substrate with the substrate movement. 1600 OFETs were fabricated on a 4-inch size wafer. Reprinted with permission from reference 28, copyright 2019 Nature. C) Water-surface drag coating method. A discrete OSC/PS film was used as the sacrificial film to control solvent spread. The triggered the spread of solution by dragging at the contact line pushed the nuclei to move. At the same time, with the solvent evaporation at the contact line, a crystal was gradually grown. Reprinted with permission from reference 29, copyright 2019 Wiley. D) Simple solution shearing method and semiconductor patterned method by the resist. Water-soluble resist was printed onto crystal films. And then unprotected layer was etched by organic solvent /oxygen plasma. Last, the resist was removed by ultrapure water. Reprinted with permission from reference 35, copyright 2020 Wiley.

The potential to control the thickness of the organic thin-film down to the monolayer is another attractive aspect of the solution shearing method, which can minimize the short channel effect when scaling down the channel dimensions as a thin or monolayer channel.19 The access resistance (Racc) component in the contact resistance (Rc) can also be minimized by the monolayer channel. Previously, a monolayer C10-DNTT single crystal has been demonstrated by solution shearing, attaining a width normalized contact resistance as low as 40 W-cm.11 Besides Racc, the other component in the contact resistance is the interface resistance (Rint) between the metal electrode and the organic semiconductor. The Rint exists because of the mismatch of the work function of metal and organic semiconductors (OSC) energy levels. Yamamura et al. addressed this by inserting a dopant layer of 2,3,5,6-tetrafluoro-7,7,8,8-tetracyanoquinodimethane (F4-TCNQ, Product Number 376779) or 1,3,4,5,7,8-hexafluoro-tetracyanonaphthoquinodimethane (F6-TNAP) between the metal/OSC (C9–DNBDT–NW) interface.30

Another critical parameter in the operation of an OFET is the SS. It describes the amount of supply voltage that could increase the current value of one order near the transistor turn-on regime. Besides low voltage consumption, a small SS can also ensure a ‘sharp peak’ in the gain while the transistor operates as an inverter and improves the signal-to-noise ratio in measurement. The SS can be defined as,31

where kT/q is the thermal voltage, Dt is the defect trap density (eV)-1cm-2, and Ci is the gate dielectric capacitance (nF cm-2). The reported SS of most solution shearing OSC OFETs is within the range of 100–500 mV Dec-1 on the SiO2 dielectric.11,28,32 To further reduce the SS, a high-quality high-κ dielectric developed by atomic layer deposition (ALD) or other methods is needed. Another way to get a small SS is to decrease the trap density of the OSC/dielectric interface. Hydrophobic dielectric is suitable for achieving low trap density, which also helps to improve the device operation stability. However, this is a challenge for solution shearing because of the poor wettability. In a recent report, an extended meniscus printing method can deposit organic crystals onto hydrophobic CYTOPTM surface and a SS value close to the thermotical value of 60 mV Dec-1 has been achieved.18

Future of Organic Field-Effect Transistors

Organic transistors have expanded their application horizon due to the continuous development of new organic molecules, dielectric insulators, and new fabrication methods. With their high gain and biocompatibility, OFETs are highly suitable for next-generation biosensor devices. The functional groups of these sensors can be integrated onto the active layer molecules directly or by using new OFET structures.33,34 The use of OFETs at the human-machine interface is another exciting application with significant potential. The structure of the human and animal brain is highly susceptible to rigid interface device components, triggering an immune response and restricting long-term usage. A flexible or even conformal active layer can suppress the immune response and lead to a biocompatible device for long-term application. Miniaturization is another future direction in the development of OFETs and is a critical and essential step towards high device density for advanced functionality like 2D sensor array and circuits. Several critical aspects still need to be addressed in OFET development, including the size of the OFET, the contact effect, the short channel effect, and patterning techniques, requiring breakthroughs in the material system, fabrication process, and device operating physics.

References

Pour continuer à lire, veuillez vous connecter à votre compte ou en créer un.

Vous n'avez pas de compte ?