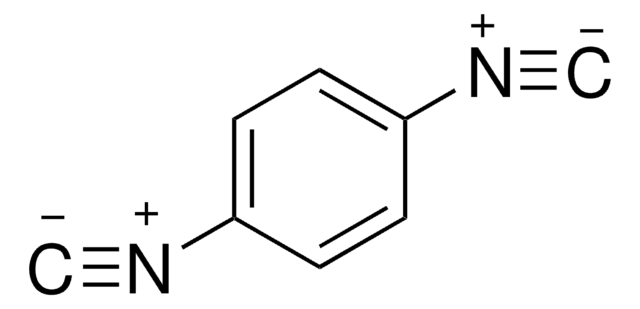

262242

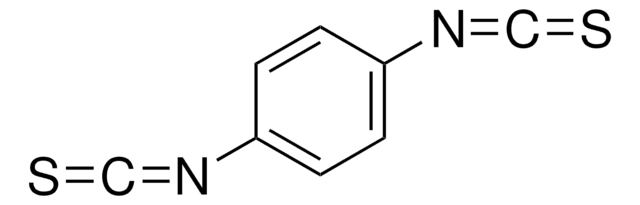

1,4-Phenylene diisocyanate

Synonym(s):

1,4-Diisocyanatobenzene, p-Phenylene diisocyanate

About This Item

Recommended Products

vapor pressure

<0.01 mmHg ( 20 °C)

Quality Level

form

solid

bp

260 °C (lit.)

mp

96-99 °C (lit.)

solubility

THF: soluble

acetone: soluble

ethyl acetate: soluble

toluene: soluble

functional group

isocyanate

SMILES string

O=C=Nc1ccc(cc1)N=C=O

InChI

1S/C8H4N2O2/c11-5-9-7-1-2-8(4-3-7)10-6-12/h1-4H

InChI key

ALQLPWJFHRMHIU-UHFFFAOYSA-N

Related Categories

Application

- A reactant to synthesize high yield polymers via criss-cross addition polymerization reaction with alkyl aldazines in pyridine.

- An organic building block to prepare adamantyl-containing diurea and thiourea derivatives applicable as potent mammalian and human soluble epoxide hydrolase inhibitors.

- A coupling agent to synthesize polyethylene glycol (PEG)/silica composite material using dibutyltin dilaurate (DBTDL) as a catalyst.

It can also be used:

- As a cross-linking reagent to investigate the mechanism of enzyme immobilization on silanized surfaces.

- In the synthesis of the dipodal bis-urea receptor, a selective receptor for hydrogen sulfate.

- In the deposition of polyurea resists films via molecular layer deposition.

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 2 Inhalation - Aquatic Chronic 2 - Eye Irrit. 2 - Resp. Sens. 1 - Skin Irrit. 2 - Skin Sens. 1

Storage Class Code

6.1A - Combustible acute toxic Cat. 1 and 2 / very toxic hazardous materials

WGK

WGK 3

Flash Point(F)

>235.4 °F - closed cup

Flash Point(C)

> 113 °C - closed cup

Personal Protective Equipment

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

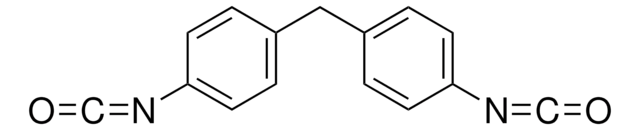

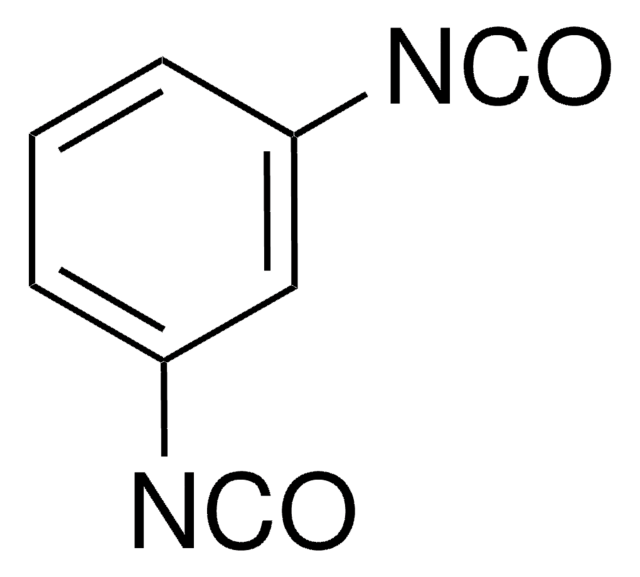

Customers Also Viewed

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service