900151

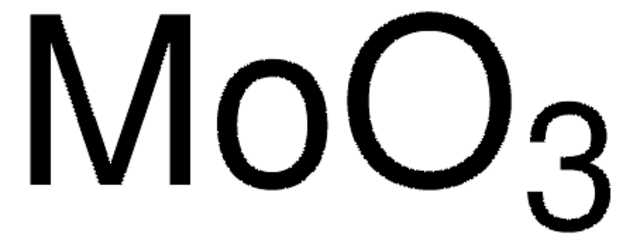

Molybdenum oxide nanoparticle ink

Synonym(s):

MoO3 Dispersion, MoO3 ink, MoO3 nanoparticle ink, MoO3 suspension

About This Item

Recommended Products

form

dispersion

Quality Level

composition

Solid content, 2.3-2.7 wt. % (crystalline MoO3 in ethanol)

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

particle size

10-40 nm

viscosity

1-3 cP

greener alternative category

, Enabling

Related Categories

General description

Application

Caution

- Store in a dark at room temperature.

- Prior to application: shake then ultrasonicate with sonic horn and (optionally) filter through 0.45 μm PTFE filter.

- Post-treatment: use plasma cleaning of dry films for removal of organic dispersant.

Legal Information

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Carc. 2 - Eye Irrit. 2 - Flam. Liq. 2

Storage Class Code

3 - Flammable liquids

WGK

WGK 2

Flash Point(F)

57.2 °F

Flash Point(C)

14 °C

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Professor Shinar (Iowa State University, USA) summarizes the developments of a variety of sensor configurations based on organic and hybrid electronics, as low-cost, disposable, non-invasive, wearable bioelectronics for healthcare.

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Recent progress in the area of solution-processed functional materials has led to the development of a variety of thin-film optoelectronic devices with significant promise in the industrial and consumer electronics fields.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service