Stretchable Electroluminescent Devices

Hexing Yin, Qibing Pei

Soft Materials Research Laboratory, Department of Materials Science and Engineering, Henry Samueli School of Engineering and Applied Science, University of California, Los Angeles, CA 90015, USA

Material Matters™, 2021, 16.3 | Material Matters™ Publications

Introduction

Electroluminescent (EL) devices date back more than a century ago, to when H. J. Round applied an electrical bias on a carborundum crystal and observed a yellowish glow. Since then, many materials have been investigated for use in fabricating EL devices. Today, displays based on organic light-emitting diodes (OLEDs) proliferate the consumer market, from watches to large-screen television sets. The latest OLED displays provide enhanced efficiency, color range, and lifetime. Besides these performance metrics, deformability has been gaining increasing attention for EL devices. Deformable displays are poised to create new opportunities in the automotive and mobile device industry. Conventional EL devices have limited deformability due to the rigidity of both the EL materials and electrodes. In 1992, the first flexible OLED was reported using conductive polyaniline (PANI, Product Number 912891) on polyethylene terephthalate (PET) substrate as the anode, poly[2-methoxy-5-(2-ethylhexyloxy)-1,4-phenylenevinylene] (MEH-PPV, Product Number 541435) as EL layer, and calcium as the cathode.1 The multilayer thin film structure based primarily on polymers was the key to achieving its flexibility. Through tremendous efforts in the following 30 years, numerous companies have developed prototypes of flexible displays that can be bent, folded, or even rolled up. Samsung and Huawei have recently introduced smartphones with a foldable OLED display screen.

Researchers are now working to further stretch the deformability spectrum by developing EL devices that can be elongated. Unlike flexible devices, which only need to bear a few percent of bending strain, stretchable devices must undergo at least 10% strain and can thus be twisted, crumpled, and expanded to increase the display area. The high mechanical compliance may be uniquely suitable for conformably attaching electronic devices to dynamic and curvilinear surfaces.2 For example, while wearable devices like smartwatches today are still rigid and bulky, future smartwatches with stretchable displays may be worn as a wrist band and can deform along with skin to offer intimate human-machine communication. However, despite the high demand and enthusiasm, challenges remain to simultaneously achieve high stretchability and high device performance.

There are two general categories of stretchable EL devices to achieve stretchability. One is enabled through novel geometry and structure, which typically comprise discrete rigid EL elements and stretchable interconnects. The other type is an intrinsically stretchable EL device where all key materials in the devices are stretchable. Our group demonstrated an intrinsically stretchable polymer light-emitting electrochemical cell (PLEC) and a polymer OLED (PLED). Many other groups have also reported stretchable OLEDs and phosphor particle-elastomer-based EL devices. Performance of these devices still lags behind those rigid EL devices in terms of turn-on voltage, efficiency, and lifetime. Various new materials and architectures are under development. This review offers a concise survey of the representative stretchable EL devices focusing on the key elements: electrode, EL material, and device structure.

Electrode

A wide variety of conductive materials have been explored as candidates for the electrodes of stretchable EL devices. Traditional electrode materials like gold (Au), silver (Ag), and indium tin oxide (ITO, Product Number 747939) usually crack when stretched by 5% if no stretchable geometrical design is implemented.3 Thus, developing new electrodes of low sheet resistance (< 100 Ohm sq-1), high transparency (> 80%), and high stretchability (> 20% strain) represents a significant effort of the field. A general strategy to introduce stretchability is to construct percolation networks of nanometer-scale conductive materials in an elastomer matrix. Nanoparticles (0D), nanowires (1D), and nanoflakes/nanosheets (2D) have all been considered. Among these, nanowires usually exhibit the best performance in terms of conductivity, transmittance, and stretchability, owing to their high length-to-diameter aspect ratio, which allows the formation of numerous contact junctions on each nanowire. Thus, forming a percolation network at low filler loading. Such a percolation network has large openings to transmit light, leading to high optical transmittance. Silver nanowires (AgNW, Product Number 778095) and carbon nanotubes (CNT, Product Number 791504) are among the most widely used 1D conductive fillers. They may be dispersed in common solvents, like water and isopropanol and coated on desired substrates via vacuum filtration, screen printing, spraying, spin-coating, bar, and dip coating. There is a tradeoff between sheet resistance and optical transmittance, and this can be balanced depending on specific application requirements.

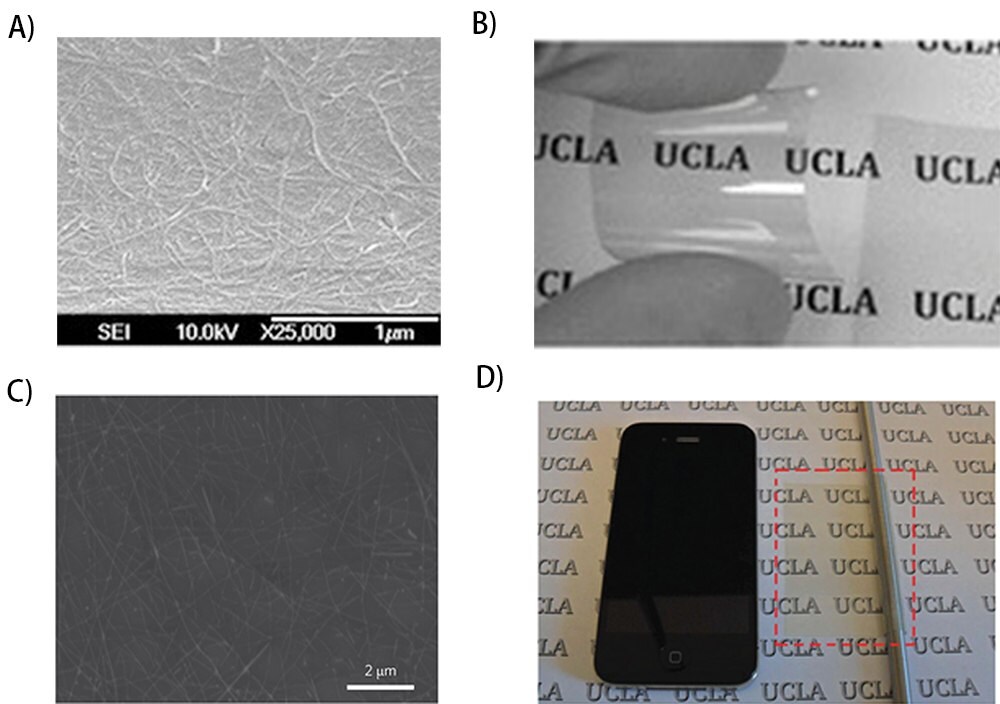

Uniformly blending the nanomaterials in an elastomer is one option for making stretchable interconnects.4 For transparent electrodes, attaching the nanomaterials to the surface or embedding in the surface layer of an elastomer is preferred. Such bilayer heterogeneous structures minimize the conductive materials required in the electrode to maintain optical transparency. This also allows the network to be patterned by dry etching, wet etching, or laser ablation. Embedding a conductive network in an elastomer surface layer reduces the surface roughness so that thin-film electronics can be fabricated on the electrode; this is significant for the fabrication of OLED devices where the emissive semiconductor layer is merely 100 nm thick. For example, Yu et al. fabricated the single-wall carbon nanotube-poly(tert-butyl acrylate) (SWCNT-PtBA) composite electrode and demonstrated the first intrinsically stretchable PLEC.5 In their experiment, SWCNTs were first bar-coated on glass and infiltrated by tert-butyl acrylate monomer, followed by polymerization via ultraviolet (UV) light exposure. Then, the PtBA film was peeled off from the glass substrate, and the SWCNT network was buried in the polymer surface (Figure 1A and 1B). The figure of merit transmittance was 87% at 550 nm wavelength with 500 Ohm sq-1 sheet resistance. The average surface roughness was less than 10 nm.

Figure 1.A) SEM image of conductive surface of the SWCNT-PtBA electrode, B) photograph of 500 Ohm sq-1 SWCNT-PtBA electrode, C) SEM image of conductive surface of the AgNW-PUA electrode, D) photograph of 15 Ohm sq-1 AgNW-PUA electrode.

PtBA is a shape memory polymer that can stretch the composite electrode by 50% strain at an elevated temperature with little sheet resistance change. Liang et al. subsequently developed a AgNW-poly(urethane acrylate) (PUA) composite electrode via a similar transfer approach.6 Admixing PUA with an ethoxylated bisphenol A dimethacrylate monomer in the formulation obtained both high elongation (~150 %) and good bonding force with AgNWs (Figure 1C and 1D). Compared to the SWCNT-PtBA electrode, the AgNW-PUA electrode provided lower sheet resistance (15 Ohm sq-1) at comparable transmittance (83% at 550 nm) and lower surface roughness (peak to valley value being 3.4 nm). The sheet resistance of the AgNW-PUA electrode increased by 23 times when the electrode was stretched to 100 % strain. In 1400 cycles of repeated stretching to 30 % strain, the electrode resistance increased from 15 Ohm sq-1 to 65 Ohm sq-1, but it recovered to 45 Ohm sq-1 after 30 min of idle time at the relaxed state.

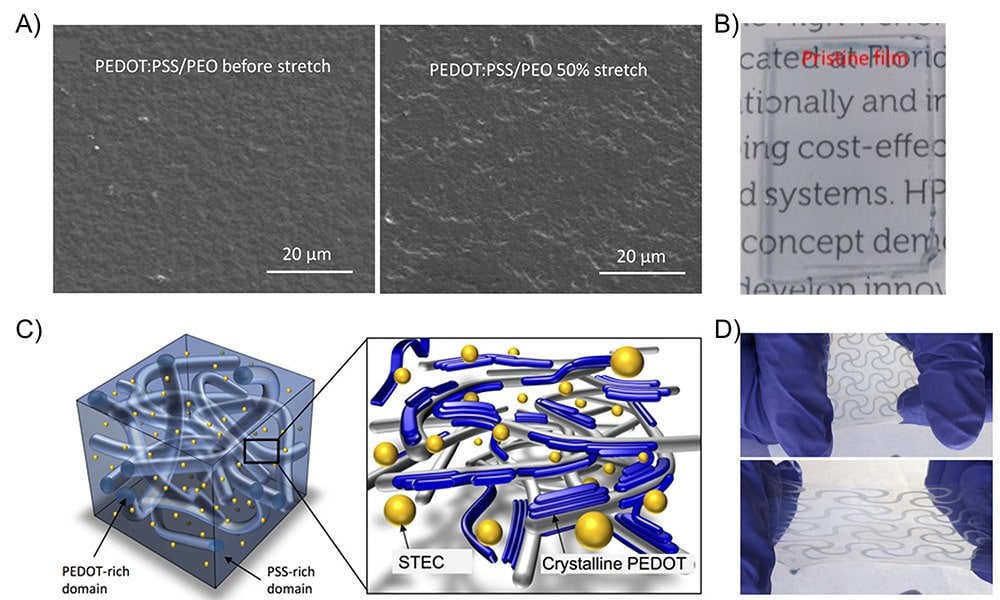

Besides the nanomaterial/elastomer composites, doped conjugated polymers have also been modified for stretchable transparent electrodes. PANI, polypyrrole (PPy, Product Number 577030), and poly(3,4-ethylenedioxythiophene):poly styrene sulfonate (PEDOT:PSS, Product Number 655201) are good examples. High conductivity is usually derived from dense and ordered packing of the conjugated polymer chains for such conductive polymers, and such microstructures diminish deformability. PEDOT:PSS, for instance, cannot survive more than 5% strain itself.7 An effective strategy is to mix the conductive polymers with a small molecule or polymer of high stretchability. Bade et al. mixed PEDOT:PSS with polyethylene oxide (PEO) to form a homogeneous solution, then spin-coated on a polydimethylsiloxane (PDMS) substrate.8 Interestingly, adding a small amount of PEO raised the conductivity of PEDOT:PSS. It is suggested that PEO might screen the Coulombic interaction between PEDOT and PSS. Phase segregation occurs where PEDOT chains change from coil to extended coil or linear.9 At 33 wt% loading of PEO, the PEDPT:PSS-PEO blend electrode showed 82% transmittance at 550 nm and 140 Ohm sq-1 (Figure 2A and 2B). The electrode could be stretched up to 40% strain with a 12% increase in resistance. Wang et al. formulated a highly stretchable and conductive PEDOT:PSS composite by incorporating ionic additives with sulfonate or sulfonimide anions (Figure 2C).4 These additives enhanced the stretchability and electric conductivity by weakening the interaction between PEDOT and PSS. PEDOT domains aggregated to form conductive pathways within the softened PSS matrix. Transmittance of 96% at 550 nm was obtained with 59 Ohm sq-1 (Figure 2D), achieving a conductivity of 4100 S cm-1 at 100% strain.

Figure 2.A) SEM images and B) Photographs of conductive surfaces of the PEDOT:PSS-PEO electrode. C) Schematic diagram representing the morphology of a stretchable PEDOT film with STEC enhancers. D) Patterned PEDOT/STEC film on SEBS (top) and stretching the film (bottom).

Ionic hydrogel can be used as the electrode in stretchable alternating current electroluminescence (ACEL) devices. Unlike PLED or PLEC, where electrons and holes are injected and recombine radiatively in the EL layer, ACEL devices generate light by a different mechanism: charge carriers are injected and accelerated in the EL layer at a high electric field, which then impacts and excites the luminescent center, where light is generated after radiative relaxation. This mechanism allows the use of low conductive electrodes in the ACEL devices. Ionic hydrogel has high transparency (~100% in the visible spectrum), low modulus, large stretchability (> 600% strain), and a small resistance increase during stretching. However, solvent or liquid in hydrogel evaporates rapidly, causing packaging and durability concerns. Larson et al. employed lithium chloride (LiCl) dissolved in a polyacrylamide (PAM) hydrogel on Ecoflex as the electrode to fabricate a hyperelastic light-emitting capacitor.10 They chose LiCl because of its moderate conductivity (~10 S m-1), ionic strength, and hygroscopic nature (helps retain water). PAM was used as a matrix due to its high toughness and high transparency. The resulting electrode had a maximum strain of 500%. The resistance increased over 400% strain was just 2.5 times that of the original value.

EL material

Emissive materials in stretchable EL devices vary along with the device category. Intrinsically stretchable light-emitting polymers (LEPs) are desired for stretchable PLED devices. Ideally, such polymers should have ambipolar charge carrier mobility, high electroluminescence quantum yield, narrow emission peak in the visible spectrum, and high stretchability. Nevertheless, semiconducting polymers with extended π-electron conjugation usually exhibit semi-crystallinity due to strong π–π stacking between neighboring chains and poor stretchability.11 Liang et al. demonstrated an intrinsically stretchable PLED with a blend of 1,3-bis[(4-tert-butylphenyl)-1,3,4-oxidiazolyl]phenylene (OXD-7) and a white LEP provided by Cambridge Display Technology, Ltd. The resulting device was soft, looked like a piece of rubber sheet, was turned on at 7 V. A high brightness of 1100 cd m-2 was obtained at 21 V, with a reported maximum current efficiency of 4.0 cd A-1.12

Another approach is blending EL polymers with additives like a small molecule, elastomer, and ionic liquid. A good example is the EL layers in the PLEC, comprising a conjugated polymer, salt, and ionic conductor. Liang et al. blended a phenyl substituted poly(1,4-phenylenevinylene) (Super yellow light-emitting PPV copolymer, Product Number 900438), ethoxylated trimethylolpropane-tri acrylate (ETPTA, Product Number 412198), PEO, and lithium trifluoromethane sulphonate (LiTf) for the stretchable PLEC emissive layer.6 While SuperYellow is stiff, the ionic conductive medium is soft and forms a dispersed phase in the SuperYellow matrix. The blend as a whole could be stretched like a sponge.13

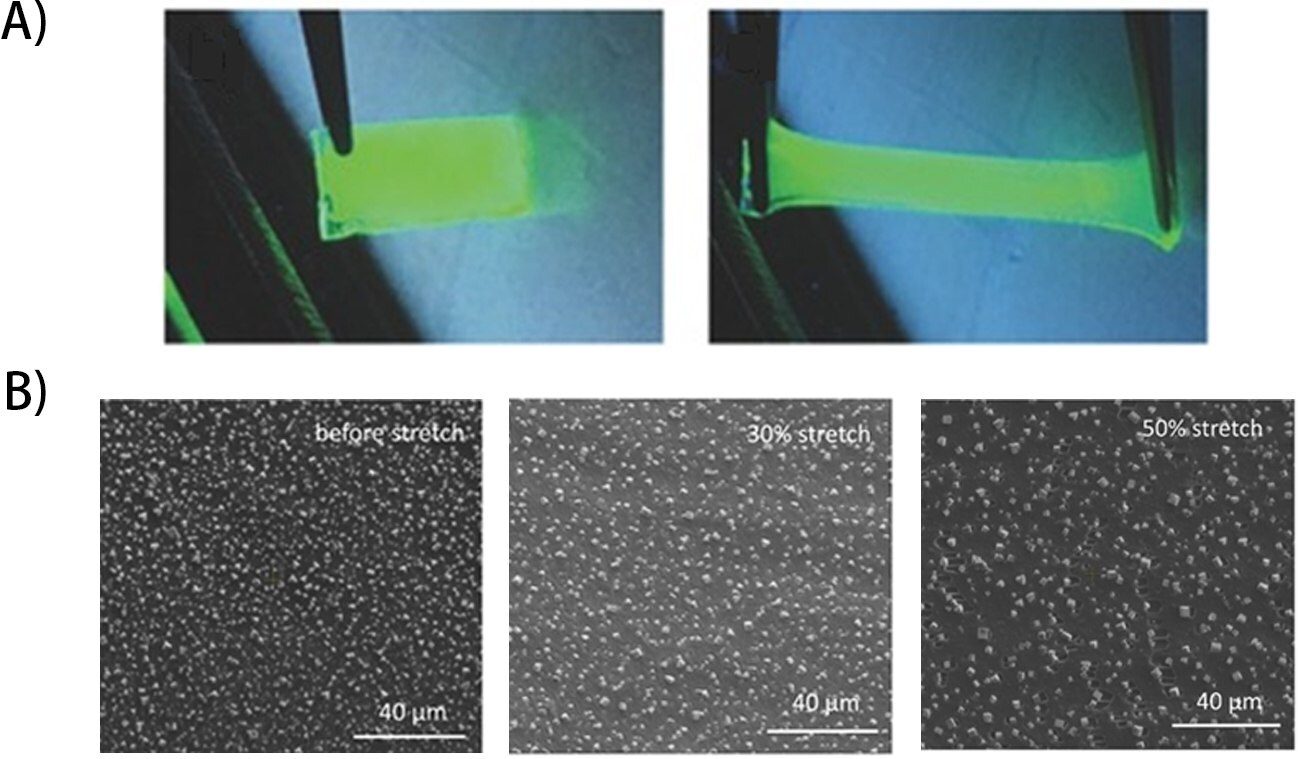

Perovskite nanocrystal-polymer composites may also be made stretchable, as shown by Bade et al., who mixed methylammonium lead tribromide (MAPbBr3) crystals with PEO as the emissive layer (Figure 3A).8 The perovskite crystals were found densely distributed in the PEO matrix (Figure 3B). This homogeneous, pin-hole-free composite film can be stretched to 50% strain.

Figure 3.A) Photos of the MAPbBr3/PEO composite film under 365 nm UV irradiation before and after stretching to ~100% strain. B) SEM images of the MAPbBr3/PEO composite thin film stretched to 0, 30%, and 50% strain.

Doped with metals like copper or manganese, ZnS phosphor powders blended with an elastomer are frequently used as EL materials in stretchable ACEL devices. To accommodate the large size of phosphor powder (diameter ~ 20 µm) and to avoid device breakdown under significant bias, the ACEL devices usually use a thick emissive layer (> 50 µm, sometimes even a few mm). The emission color can be easily tuned via dopants in ZnS. Silicone such as PDMS (Product Number 761036) and Ecoflex are favorable elastomer matrices used in ACEL devices due to their excellent stretchability and easy-handing. For example, Larson et al. employed a 1 mm thick film of a homogenous dispersion of 25 µm diameter ZnS powders in Ecoflex 00-30.10 The resulting hyperelastic light-emitting capacitor had a maximum stretchability of 487% strain. Red, green, and blue pixels were all demonstrated.

Structure-Enabled Stretchable EL Devices

Two categories of structure-enabled stretchable EL devices have been studied. One is the island-bridge structure. As the name suggested, patterned serpentine or “wavy” structures are introduced as bridges to connect rigid LED islands on an elastomer substrate. The serpentine structures deform geometrically within or out of the elastomer surface during stretching, while the rigid LEDs experience minor strain and maintain high diode performance (Figure 4A).14 One advantage of the island-bridge approach is that the conventional fabrication process fabricates the rigid EL components. A drawback of this approach is the sophisticated geometry designs of the interconnects, which incur complex fabrication routes. The dot pitch cannot be shrunk to display high-resolution images, as the rigid LEDs do not deform. The elastic spacing between them needs to be significant to obtain a sizeable overall deformation.15 Managing the strain distribution at the serpentine/island interface is also challenging.

Figure 4.A) Typical geometric design and device performance under stretching of the island-bridge structure. B) Device structure and performance under stretching of the buckled MAPbBr3 QLED.

The other type of structure-enabled stretchability can be realized by attaching a pre-fabricated ultrathin flexible EL device onto a pre-stretched elastomer substrate. After releasing the strain, the flexible EL device buckles out of plane to form a periodical wrinkle structure. Large-strain deformation is accommodated by un-wrinkling or bending deformation of the EL layer. Repeated stretching can be tolerated as the ultrathin EL device bends and flattens on the elastomer substrate. Li et al. demonstrated a stretchable perovskite QLED via this wrinkle structure method (Figure 4B).16 In this work, an ultrathin (~ 2 µm) QLED was first built on glass and then attached to a pre-stretched VHB elastomer, using MAPbBr3 QDs as the emissive layer. The device had a low turn-on voltage of 3.2 V, maximum current efficiency of 9.2 cd A-1, peak brightness of 3187 cd m-2 at 9 V, and maximum linear strain of 50%. After 1000 cycles of repeated stretch to 20% strain, the device showed minimal performance fluctuation. A critical aspect of this approach is to obtain buckles of the appropriate wavelength. Macroscopic wrinkles with wavelengths of hundreds of microns are relatively easy to obtain but are visible to the naked human eye. Buckles of small wavelength, on the other hand, have a small bending radius and can cause significant strain in the rigid emissive layers.

Intrinsically Stretchable EL Devices

Intrinsically stretchable EL devices reported so far include PLEDs, PLECs, perovskite-polymer LEDs, and ACEL devices. These devices overcome the disadvantages of low effective area and complex fabrication found with the structure-enabled stretchable EL devices. Stretchable PLED demonstrated by Liang et al. shared similar multi-stack thin-film architectures as conventional OLEDs (Figure 5A).12 In this work, PEDOT:PSS was spin-coated on AgNW-PUA anode as the hole injection layer (HIL). It also shielded solvent attack in the subsequent spin coating of the white LEP blended with OXD-7. Polyethylenimine (PEI, Product Number 408719) was spin-coated on another AgNW-PUA electrode to boost electron injection (EIL). The two AgNW-PUA films with respective polymer coatings were laminated together to complete the device fabrication. The device could be stretched by as much as 130% strain, which was irreversible. It could be stretched repeatedly at 40% strain for 100 cycles.

Figure 5.Structures and performances of the intrinsically stretchable A) PLED and B) PLEC.

HIL and EIL layers in the PLED are required to overcome hole and electron and injection barriers at the anode and cathode interfaces, respectively. These layers, as well as the EL layer, must be ultrathin to keep driving voltage low. The lamination may cause pinholes and other defects in the layers. These issues are relieved in PLECs, where forming a p-i-n junction in the emissive layer promotes charge injections without the HIL and EIL layers and allows a relatively thick EL layer.17 The stretchable PLEC demonstrated by Liang et al. was made by simply spin coating a homogenous solution of Super yellow light-emitting PPV copolymer, PEO, ETPTA, and LiTf on AgNW-PUA electrode and laminating this with another AgNW-PUA electrode (Figure 5B).6 The device showed a 6.8 V turn-on voltage, 2200 cd m-2 maximum brightness at 21 V, 5.7 cd A-1 maximum current efficiency, and stretchability up to 120% strain. It could be repeatedly stretched to 30% strain for 1000 cycles. Recently, Liu et al. demonstrated a fully stretchable active-matrix PLEC.18

The PLEC architecture does introduce new issues. One is finding a solvent that can dissolve the conjugated polymer, salt, and ionic conductor. Such solvent can typically cause swelling or cracking of the elastomeric polymer substrate. Retransferring the PLEC layer formed on a release substrate onto the stretchable electrode creates new challenges. Stretchable ACEL devices of similar architecture, however, experience less solvent attacking issues. The EL layers of ACEL devices are tens or hundreds of microns thick, which simplifies the device fabrication. Free-standing films of the EL layer and electrodes may be produced separately and then laminated together. The large thickness does lead to high driving voltage (> 100 V) and high alternating frequency (> 1 kHz). Additionally, the brightness of the ACEL devices was low. Tan et al. mixed a fluoroelastomer, poly(vinylidene fluoride-co-hexafluoropropylene) (P(VDF-HFP), with a small amount of FS-300 as the elastomer matrix with both high dielectric permittivity and stretchability to address these issues.19 The same fluoroelastomer with an ionic liquid, 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide (EMITFSI, Product Number 11291), added was used as the electrodes. The resulting ACEL device was self-healing. The device showed a turn-on voltage of 23 V with an alternating frequency below 1 kHz, maximum brightness of 1460 cd m-2 at 3750 V, and a giant stretchability of 800% strain, allowing for repeated stretching at 20% strain for 1000 cycles.

Conclusion

The transparent electrode, emissive material, and device architecture play an essential role in developing stretchable EL devices. Structure-enabled stretchable EL devices take advantage of well-developed EL devices and elastomeric interconnects for global stretchability. Efforts in this area center on designing innovative geometries to accommodate large strain while keeping the non-emissive area small. Conforming a buckled ultrathin EL layer on a pre-stretched elastomer substrate is a practical approach to large strains. The biggest challenge for intrinsically stretchable EL devices is integrating stretchable transparent electrodes and EL layers for high EL performance. Research shows that AgNWs, CNTs, doped conductive polymer, and ionic elastomer meet the surface conductivity, optical transparency, and stretchability requirements for the electrodes. Developing a stretchable EL (semiconductor) layer is still ongoing to achieve stretchable PLEDs and PLECs. Introducing stretchable microstructures to the otherwise unstretchable conjugated polymers appears to be a very promising approach. For ACEL devices, low bias, low alternating frequency, and high brightness are desired. Overall, PLEDs, PLECs, perovskite-polymer LEDs, and ACEL devices are all attractive candidates for stretchable EL devices and future stretchable displays. Further technical progress hinges on new material breakthroughs.

References

Um weiterzulesen, melden Sie sich bitte an oder erstellen ein Konto.

Sie haben kein Konto?