900741

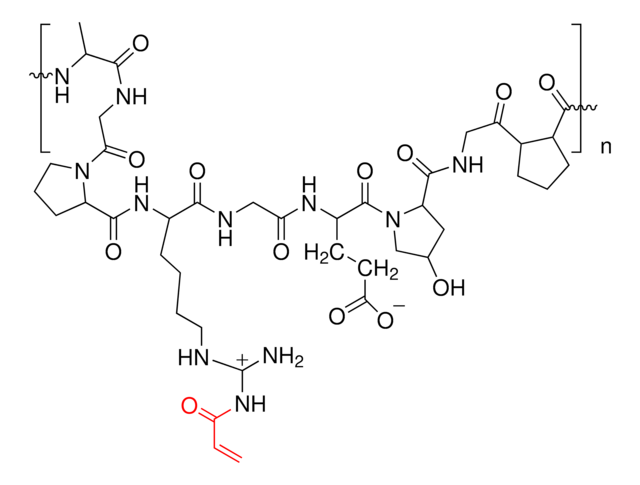

Gelatin methacryloyl

gel strength 170-195 g Bloom, degree of substitution: 60%

Sinónimos:

GelMA, Gelatin methacrylamide, Gelatin methacrylate, GelMa, Gelatin Methacrylate

About This Item

Productos recomendados

¿Está buscando productos similares? Visita Guía de comparación de productos

Categorías relacionadas

Application

Storage Class

11 - Combustible Solids

wgk_germany

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

Elija entre una de las versiones más recientes:

Certificados de análisis (COA)

¿No ve la versión correcta?

Si necesita una versión concreta, puede buscar un certificado específico por el número de lote.

¿Ya tiene este producto?

Encuentre la documentación para los productos que ha comprado recientemente en la Biblioteca de documentos.

Los clientes también vieron

Artículos

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Contenido relacionado

Tissue engineering fabricates tissues cultures from scaffolds, living cells, and biologically active molecules by simulating the microenvironment of the body to repair or replace damaged tissue.

Nuestro equipo de científicos tiene experiencia en todas las áreas de investigación: Ciencias de la vida, Ciencia de los materiales, Síntesis química, Cromatografía, Analítica y muchas otras.

Póngase en contacto con el Servicio técnico