221007

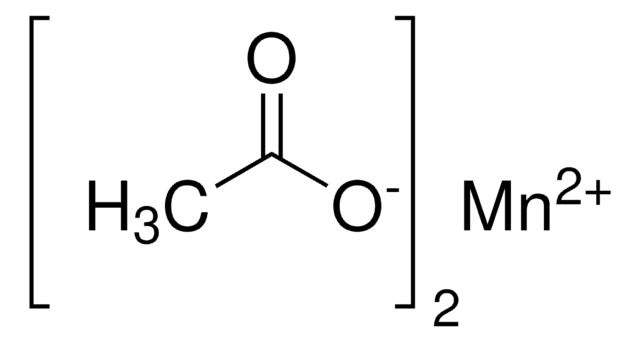

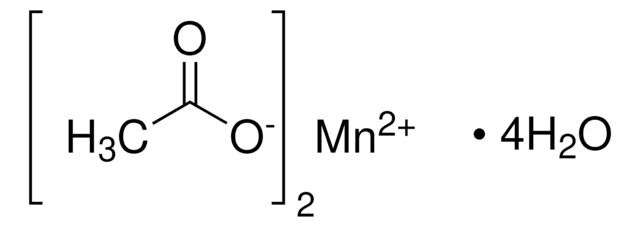

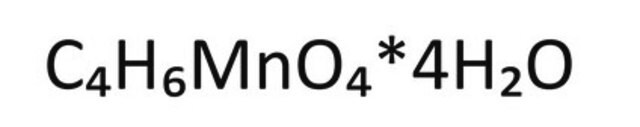

Manganese(II) acetate tetrahydrate

≥99%

Sinónimos:

Manganese Diacetate Tetrahydrate, Manganous acetate

About This Item

Productos recomendados

assay

≥99%

form

crystals

reaction suitability

core: manganese

mp

>300 °C (lit.)

density

1.589 g/mL at 25 °C (lit.)

SMILES string

[H]O[H].[H]O[H].[H]O[H].[H]O[H].CC(=O)O[Mn]OC(C)=O

InChI

1S/2C2H4O2.Mn.4H2O/c2*1-2(3)4;;;;;/h2*1H3,(H,3,4);;4*1H2/q;;+2;;;;/p-2

InChI key

CESXSDZNZGSWSP-UHFFFAOYSA-L

¿Está buscando productos similares? Visita Guía de comparación de productos

Categorías relacionadas

General description

Application

- A starting material in the synthesis of manganese carboxylates, which are used to prepare manganese oxide thin films by chemical vapor deposition (CVD).

- A precursor in the synthesis of manganese-TiO2 composites by chemical vapor condensation (CVC).These composites are used in the oxidation of NO at low temperatures.

- A precursor in preparation of NCM (LiNi1/3Co1/3Mn1/3O2) powder applicable as cathode material in lithium-ion batteries.

- A starting material for the synthesis of LiMn2O4 (LMO) film on Au substrate by sol-gel method.

signalword

Warning

hcodes

Hazard Classifications

Aquatic Chronic 3 - STOT RE 2 Inhalation

target_organs

Brain

Storage Class

11 - Combustible Solids

wgk_germany

WGK 2

flash_point_f

Not applicable

flash_point_c

Not applicable

ppe

dust mask type N95 (US), Eyeshields, Gloves

Elija entre una de las versiones más recientes:

¿Ya tiene este producto?

Encuentre la documentación para los productos que ha comprado recientemente en la Biblioteca de documentos.

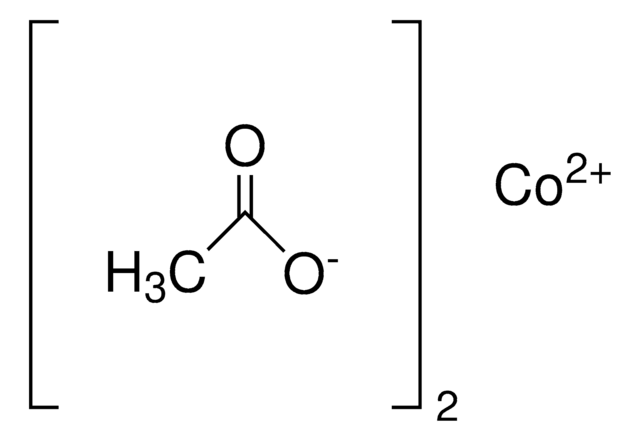

Los clientes también vieron

Nuestro equipo de científicos tiene experiencia en todas las áreas de investigación: Ciencias de la vida, Ciencia de los materiales, Síntesis química, Cromatografía, Analítica y muchas otras.

Póngase en contacto con el Servicio técnico