441090

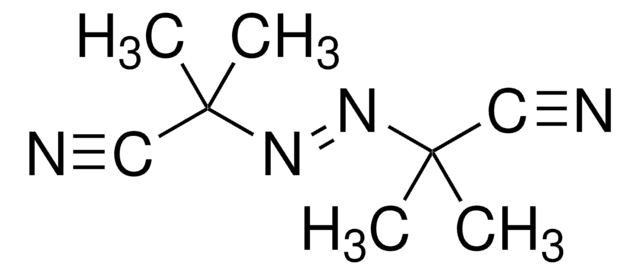

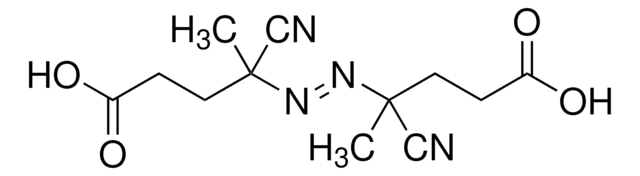

2,2′-Azobis(2-methylpropionitrile)

98%

Synonym(s):

α,α′-Azoisobutyronitrile, AIBN, Azobisisobutyronitrile, Free radical initiator

About This Item

Recommended Products

assay

98%

form

powder

mp

102-104 °C (dec.) (lit.)

storage temp.

2-8°C

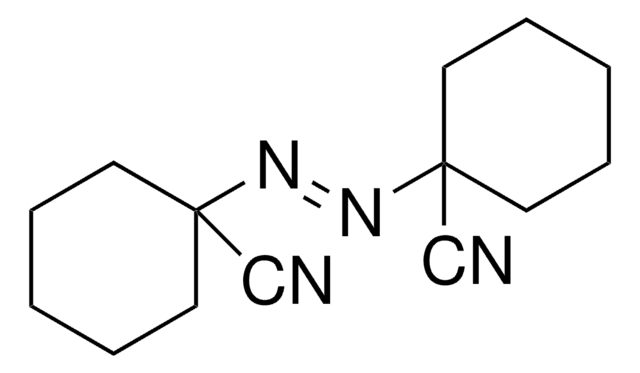

SMILES string

CC(C)(\N=N\C(C)(C)C#N)C#N

InChI

1S/C8H12N4/c1-7(2,5-9)11-12-8(3,4)6-10/h1-4H3/b12-11+

InChI key

OZAIFHULBGXAKX-VAWYXSNFSA-N

Looking for similar products? Visit Product Comparison Guide

Application

- Polystyrene by soap-free emulsion polymerization.

- Molecularly imprinted polymer(MIP) using 1-vinyl imidazole. MIP can be used to quantify acid violet 19 dye in river water samples.

Storage and Stability

signalword

Danger

hcodes

Hazard Classifications

Acute Tox. 4 Inhalation - Acute Tox. 4 Oral - Aquatic Chronic 3 - Self-react. C

supp_hazards

Storage Class

4.1A - Other explosive hazardous materials

wgk_germany

WGK 2

flash_point_f

122.0 °F

flash_point_c

50 °C

ppe

dust mask type N95 (US), Eyeshields, Faceshields, Gloves, type P3 (EN 143) respirator cartridges

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

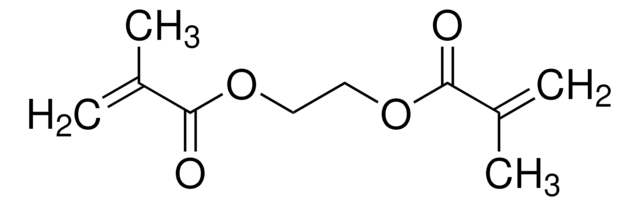

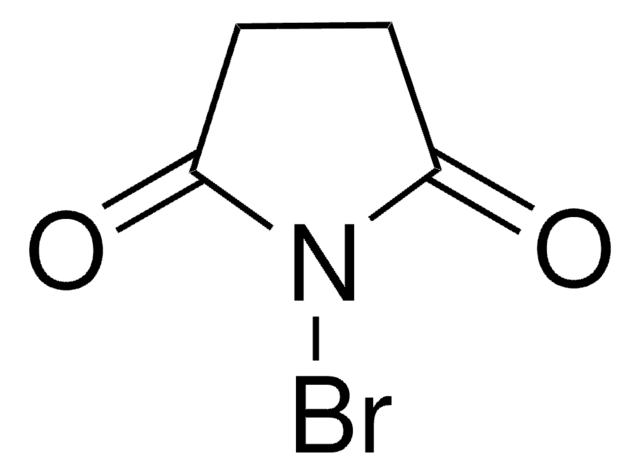

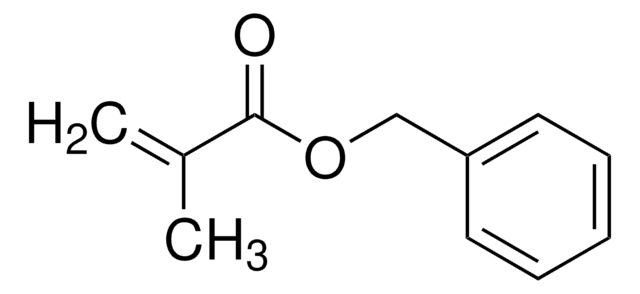

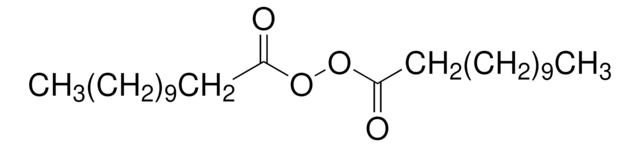

Customers Also Viewed

Articles

To keep pace with Moore′s Law, there is a continuing need in the semiconductor industry to achieve higher circuit density in microelectronic devices.

An article regarding common FAQs for initiators and stabilizers.

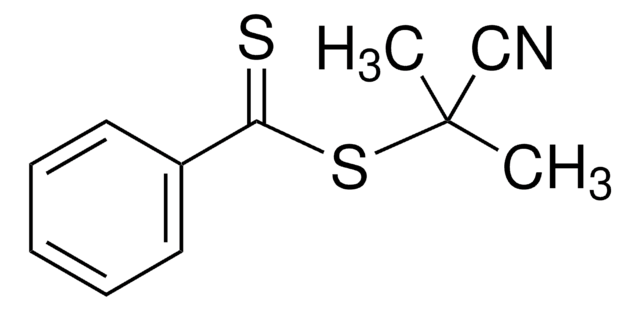

RAFT (Reversible Addition Fragmentation chain Transfer) polymerization is a reversible deactivation radical polymerization (RDRP) and one of the more versatile methods for providing living characteristics to radical polymerization.

The manufacture of monomers for use in ophthalmic applications is driven by the need for higher purity, improved reliability of manufacturing supply, but ultimately by the need for the increased comfort, convenience, and safety of contact lens wearers. Daily wear contact lenses have the potential to fill this need for many customers; however, their widespread use is constrained by higher costs compared to weekly- or monthly-based lenses. New approaches that improve cost structure and result in higher quality raw materials are needed to help make contact lenses more affordable and accelerate growth of the contact lens market.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service