Heavy Metal Analysis of Cannabis sativa by ICP-MS and the Need for Proper Sample Homogenization

Stephan Altmaier, Principal Scientist Advanced Analytical R&D

Merck

Abstract

A step-by-step protocol for the analysis of various heavy metals in Cannabis sativa plant material by ICP-MS was developed. Cannabis is known to accumulate metals in various parts of the plant, such as seeds, leaves or stems, to a different extent. As a consequence, several protocols for the homogenization of cannabis buds were developed in order to prepare reproducible samples and analysis results. For comparison, cannabis buds were separated into seeds, stems, and leaves and the plant parts were subjected to ICP-MS.

Introduction

Cannabis is a plant genus that consists of three different species (Cannabis sativa, indica and ruderalis) and all of these are known to accumulate heavy metals in different parts of the plant (roots, leaves, seeds etc.). Due to this ability cannabis has been used for the remediation of contaminated soil (phytoremediation and phytoextraction).1,2,3,4 On the other hand this inclination can hinder the use of cannabis in the food or medical industry. Therefore, all plant materials used in either food or pharma products, should be tested for their heavy metal content.

As of July 2020, 24 US states and Canada issued regulations for the testing of heavy metal content in cannabis, and all of them provided limits for arsenic, cadmium, lead and mercury metals (referred to as the “big four”). In addition, several states have set limits for one or more of these metals: chromium, barium, silver, selenium, antimony, copper, nickel and zinc.

Dried cannabis plant material is a very inhomogeneous matter and consists of leaves, buds including resin, stems of various thickness and seeds. All these plant parts accumulate heavy metals to a different extent. As it was shown in numerous studies, the heavy metal uptake depends on both the plant part and the element.1,5,6 In addition, uptake is influenced by external factors such as fertilization and liming,1 ultimately causing an uneven distribution of metals throughout the plant. Hence, if the focus of studies is on the overall heavy metal content of cannabis, the material needs to be thoroughly homogenized before sample analysis. The recommended process for this sample breakdown is grinding. Various milling techniques exist, each differing in their technical complexity, such as mortar and pestle, rolling pin, knife mill, cutting mill, rotor mill, and ball mill.

Experimental Method

In this paper, a four-step workflow was applied for the process of sample homogenization, standardization, sample digestion, and analysis.

The cannabis resins which have a sticky, smearing appearance make it necessary to always freeze samples prior to milling.

Freezing can either be accomplished at -20 °C in a freezer, by making use of dry ice (-78 °C) or by utilizing liquid nitrogen (-196 °C) as a cooling agent.

The setup of any grinder must be performed according to the target analytes. For the analysis of the big four heavy metals, irrespective of the type of grinder chosen, stainless steel tools can be used. In contrast, if the abundance of additional metals such as Cr or Ni in a sample is of interest, knife mills with titanium blades or mills with grinding tools made of ZrO2 or PTFE need to be selected. As these tools are normally smaller in size, the milling process is more time consuming.

The seeds of the cannabis species are the plant part that is most potent and is investigated in this homogenization study.

Four different grinding methods were applied for the milling of three Cannabis sativa hemp varieties. ICP-MS was used to determine the heavy metal content of the samples and based on the results the homogenization efficiency of all approaches was compared. In a second set of experiments, one hemp variety was separated into seeds, leaves, and stems, followed by ICP-MS analysis to identify possible variations of heavy metal concentrations in the different plant parts.

Sample Homogenization / Milling

Three different Cannabis sativa varieties: “Finola”, “Felina” and “Santhica”, were purchased from a drug store. All of them were qualified as industrial hemp per German regulation and were sold as "hemp flowers”. The samples were obtained as 25 g batches of dried buds. The experiments for the analysis of homogenization efficiencies of milling and grinding techniques were performed by applying four different methods, described below:

- Rolling pin (RP)

- Mortar and pestle (MP)

- Knife mill (KM)

- (Cryo) Ball mill (CM)

All four procedures are very different in terms of their speed, throughput, and ability to provide homogeneous samples in a reproducible way. In addition, using the knife mill can lead to an increase in sample temperature and hence in a change of sample composition. This needs to be considered, if samples are meant to be subjected not only to ICP-MS, but also to HPLC or GC analysis (e.g., for the determination of cannabinoid or terpene content). The detailed proceedings for each of the milling techniques applied are described in the following sections.

Rolling Pin

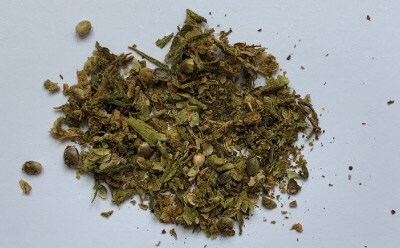

Approximately 10 g of dried buds were weighed into an airtight zip bag and cooled in a freezer at -20 °C for one hour. Subsequently the bag was placed on a hard support and the sample was ground using a wooden household rolling pin. After three to five minutes no further sample breakdown was observed and the process was stopped. Stems in the sample needed to be broken into shorter pieces of approximately 10 mm length by hand. An image of the final sample revealed rather large pieces of stem segments and undamaged seeds in an overall inhomogeneous material (Figure 1).

Figure 1.Hemp buds “Finola” after three minutes grinding using a wooden rolling pin.

Mortar and Pestle

Approximately 10 g of aliquoted, dried buds were weighed into an airtight zip bag and cooled in a freezer at -20 °C for one hour. Then one or two buds were withdrawn from the bag, placed in a china mortar and ground for five minutes utilizing a porcelain pestle. The resulting coarse powder still contained large pieces of rigid stems, which needed to be broken by hand in order to obtain shorter pieces of approximately 10 mm length. The entire process was repeated, until a 10 g sample had been prepared. Rather large pieces of stem material were visible in the otherwise homogeneous, final sample.

Knife Mill

For knife milling 18 g of hemp buds were placed in a mill equipped with titanium blades and ground for 30 seconds at 4,000 rpm (one cycle) or 10,000 rpm (two cycles), respectively. The 30 sec/4000 rpm method resulted in a sample that looked similar to that obtained with the rolling pin. In contrast, the 30 sec/10,000 rpm milling process generated a coarse powder comparable to ground coffee beans, with no stem segments or seeds visible.

(Cryo) Ball Mill

One hemp bud (approx. 2.5 g) was manually broken into pieces and placed into a 50 mL stainless steel milling beaker. A 25 mm stainless steel milling ball was added and the sealed beaker was mounted to a cryo ball mill equipped with a liquid nitrogen filling system. The grinding parameters were as follows: Pre-cooling at 5 Hz, two cycles of 90 s at 30 Hz and 30 s at 5 Hz (for intermediate cooling). This process resulted in a very fine powder with a particle size of <100 µm (Figure 2).

Figure 2.Hemp buds “Finola” after grinding in a cryo ball mill. Resulting particle size <100 μm.

For a second set of experiments, the hemp variety “Santhica” was manually separated into seeds, leaves, and stems to identify possible variations of heavy metal concentrations in the different plant parts (Figure 3).

Figure 3.Cannabis sativa “Santhica” separated into leaves (top), stems (middle) and seeds (bottom).

These samples were directly subjected to digestion (without a preceding grinding step) and then analyzed by ICP-MS.

Digestion of samples

All hemp samples were digested as follows: 50 (±1) mg of ground sample was weighed into a microwave vial and after addition of 3 mL nitric acid (65%), 1 mL hydrogen peroxide (30%) and a metal spiking solution, the sample was digested. After completion of digestion, the solution was quantitatively transferred into a 50 mL polypropylene tube, and 50 µL of indium internal standard solution was added. The final solution was then brought up to 50 mL final volume with ultrapure water. For detailed microwave digestion conditions please contact the author.

Preparation of standard solutions

In order to compensate for sample matrix effects, a standard addition approach utilizing various Certified Reference Material Heavy Metal Mix TraceCERT® standard solutions was applied for the preparation of all calibration curves. The final calibration curve covered a range from 1-20 μg/g total of heavy metals. The curve comprised of four data points; three standard addition solutions plus one unspiked sample solution. Alternatively, standard solutions were also prepared by using ICP Certipur® single element standards and ICP TraceCERT® single element standards (data not shown). For accuracy reasons, the composition of the addition solutions was adjusted to the heavy metal concentration in each of the three samples.

ICP-MS Analysis

Analysis of samples, standards, and spikes was done by ICP-MS. For detailed conditions kindly contact the author.

The analysis was performed in the sequence: Blank, sample 1 – x, additions. The resulting calibration curves for As, Cd, Hg, and Pb revealed excellent linearity over the entire calibration range, with r2 values of > 0.9995 for all.

Addition Solution for the Determination of Recovery Rates

The recovery rates for the big four heavy metals are listed in Table 1. All recoveries were in the range of ±10%.

Results & discussion

Seed Milling Method Investigation

The heavy metal content of the three hemp varieties that were subjected to the different milling processes are listed in Table 2.

The mercury content of all samples was below the limit of detection, and only one sample, out of the 14 samples displayed a cadmium level above the detection limit (0.1 µg/g). For arsenic the results were similar, with five samples containing As close to the LOD (0.1 µg/g). The findings for lead were a bit different, and the detected concentrations ranged from 0.3 to 1.0 µg/g. It is noteworthy, that these values do in part exceed the limits of various US states and Canada by a factor of 2-3 (depending on the intended use). The analysis of the “big four” elements was reproducible, and except for one deviation (Pb content of hemp variety “Felina” ground with MP) the milling technique did not affect the detected heavy metal concentrations.

Cryo milling was performed utilizing stainless steel equipment and resulted in the detection of elevated levels of chromium in all cryo-ground samples. Though nickel is also a content of stainless-steel alloys, increased amounts (compared to RP and MP milling) were only found in the “Finola” sample. This result can be attributed to the difference in grinding time. Some US states (as of now MI, MD, MO, NY) issued regulations, which make the analysis of chromium in cannabis necessary. In this case, it is essential to utilize a cryo milling approach and zirconia or PTFE grinding equipment in order to avoid sample contamination. In contrast to cryo milling, knife milling was performed (highlighted in Table 2) using titanium blades and therefore did not affect the Cr (and Ni) content of cannabis samples.

Plant Part Analysis

The heavy metal content of stems, seeds, and leaves of the hemp variety “Santhica” and the respective recovery rates are listed in Table 3. All results but the lead content of seeds are in line with the data shown in the previous section. This finding corresponds to results published in various publications, that also reported the Pb concentration in seeds being lower than in other plant parts such as leaves, stems, flowers, or roots.5,6

Conclusion

This work demonstrates a comprehensive ICP-MS workflow, using the standard addition calibration method, for the determination of heavy metals in Cannabis sativa hemp variety plant materials. Critical elements in the process include homogenization of samples and use of accurate traceable Certified Reference Material mixes, that are tailored to state specific regulations for heavy metals in cannabis. Reproducible samples were prepared by grinding cannabis with different mill types and techniques. Samples were then digested utilizing a specific digestion protocol, optimized to provide clear digestion solutions. The resulting solutions were subjected to ICP-MS analysis. Calibration data was obtained by the preparation and analysis of standard addition solutions obtained by diluting various different heavy metal CRM mixes containing arsenic, cadmium, lead and mercury. The final results were consistent for all samples and revealed an As, Cd, and Hg concentration of <0.1 to 0.1 µg/g. The detected lead content of the three cannabis varieties ranged from 0.3 to 1.0 µg/g.

To read more about our complete offer for Cannabis testing visit us at SigmaAldrich.com/Cannabis

References

To continue reading please sign in or create an account.

Don't Have An Account?