ERMEC591

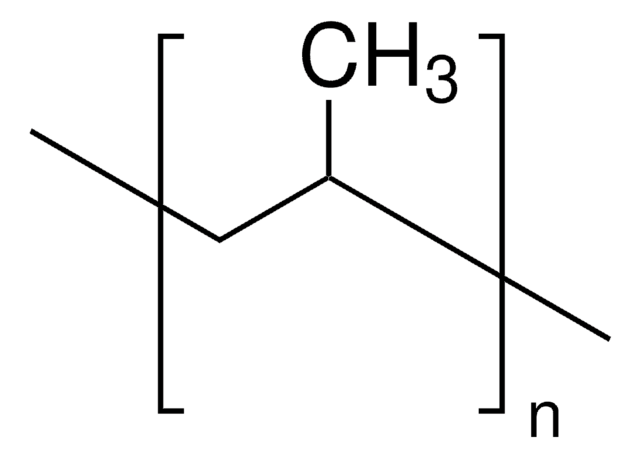

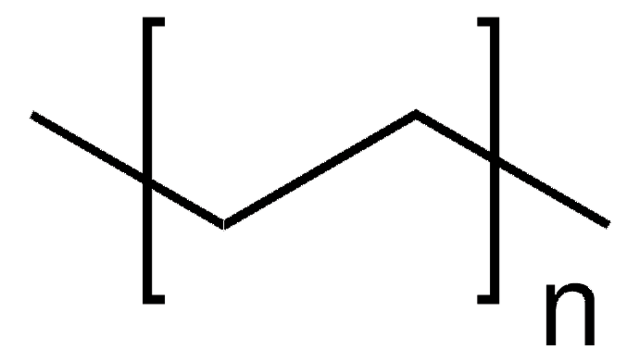

Polypropylene (PP)

ERM®, certified reference material

Synonym(s):

Polypropylene

About This Item

Recommended Products

grade

certified reference material

Agency

ERM®

manufacturer/tradename

JRC

density

0.9 g/mL at 25 °C (lit.)

application(s)

chemicals and industrial polymers

format

neat

storage temp.

−20°C

SMILES string

CC=C

InChI

1S/C22H42O3/c1-2-3-4-5-11-14-17-20-21(25-20)18-15-12-9-7-6-8-10-13-16-19-22(23)24/h20-21H,2-19H2,1H3,(H,23,24)/t20-,21+/m1/s1

InChI key

NSYDMBURIUSUDH-RTWAWAEBSA-N

Looking for similar products? Visit Product Comparison Guide

Analysis Note

ERMEC591

Legal Information

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service