Recommended Products

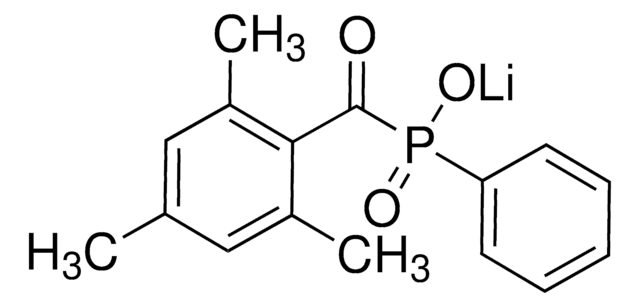

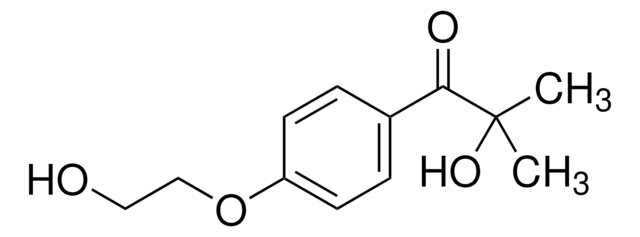

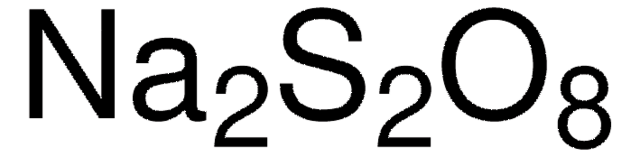

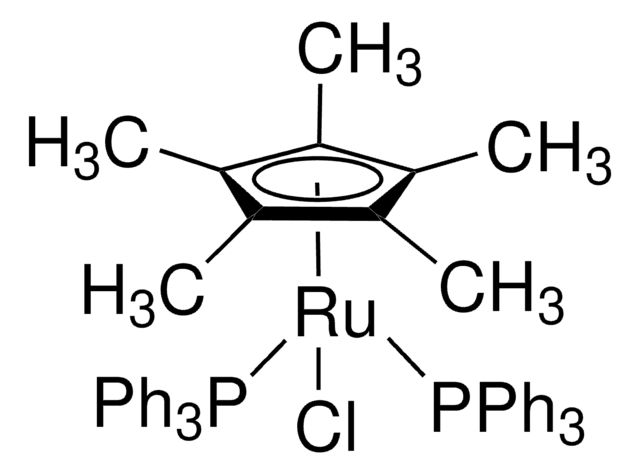

composition

Ruthenium (200 mg)

Sodium persulfate photoinitiator (1 g)

Quality Level

Application

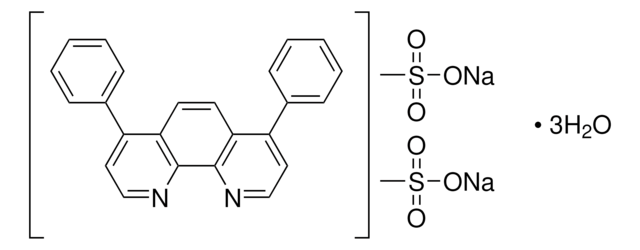

Ruthenium is a photoinitiator that utilizes visible light photocrosslinking (400-450nm) to covalently crosslink free tyrosine and acryl groups. Ruthenium photoinitiator has been tested on collagen type I, gelatin, silk fibroin, methacrylated hyaluronic acid, methacrylated gelatin, methacrylated collagen type I and PEGDA. Ruthenium is water soluble and yields better cytocompatibility, and crosslinking efficiency. Ruthenium is red/yellow/orange in color and will change the color of your solutions, hydrogels, or printed constructs. The Ruthenium photoinitiator kit is non-sterile. Adding antibiotics to your cell culture system, or sterile filtering is recommended. To sterile filter, resuspend the entire volume of ruthenium and Sodium persulfate (separately) and filter through small 0.2 micron button filters (separately). Use the sterile photoinitiator within 2 weeks. Ruthenium photoinitiator kit is ideal for tissue engineering, cell culture, and bioprinting, where tuning the mechanical properties of the substrate is required. The kit provides enough photoinitiator for >200 mL of bioinks/hydrogels.

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 4 Oral - Ox. Sol. 3 - Resp. Sens. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

5.1B - Oxidizing hazardous materials

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

J D Parker et al.

The bone & joint journal, 100-B(3), 404-412 (2018-03-29)

The intra-articular administration of tranexamic acid (TXA) has been shown to be effective in reducing blood loss in unicompartmental knee arthroplasty and anterior cruciate reconstruction. The effects on human articular cartilage, however, remains unknown. Our aim, in this study, was

Automated 3D bioassembly of micro-tissues for biofabrication of hybrid tissue engineered constructs.

N V Mekhileri et al.

Biofabrication, 10(2), 024103-024103 (2017-12-05)

Bottom-up biofabrication approaches combining micro-tissue fabrication techniques with extrusion-based 3D printing of thermoplastic polymer scaffolds are emerging strategies in tissue engineering. These biofabrication strategies support native self-assembly mechanisms observed in developmental stages of tissue or organoid growth as well as

J Parrish et al.

Lab on a chip, 18(18), 2757-2775 (2018-08-18)

Traditional 2D monolayer cell cultures and submillimeter 3D tissue construct cultures used widely in tissue engineering are limited in their ability to extrapolate experimental data to predict in vivo responses due to their simplistic organization and lack of stimuli. The

Khoon S Lim et al.

Biofabrication, 10(3), 034101-034101 (2018-04-26)

Lithography-based three-dimensional (3D) printing technologies allow high spatial resolution that exceeds that of typical extrusion-based bioprinting approaches, allowing to better mimic the complex architecture of biological tissues. Additionally, lithographic printing via digital light processing (DLP) enables fabrication of free-form lattice

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service