Extractables and Leachables

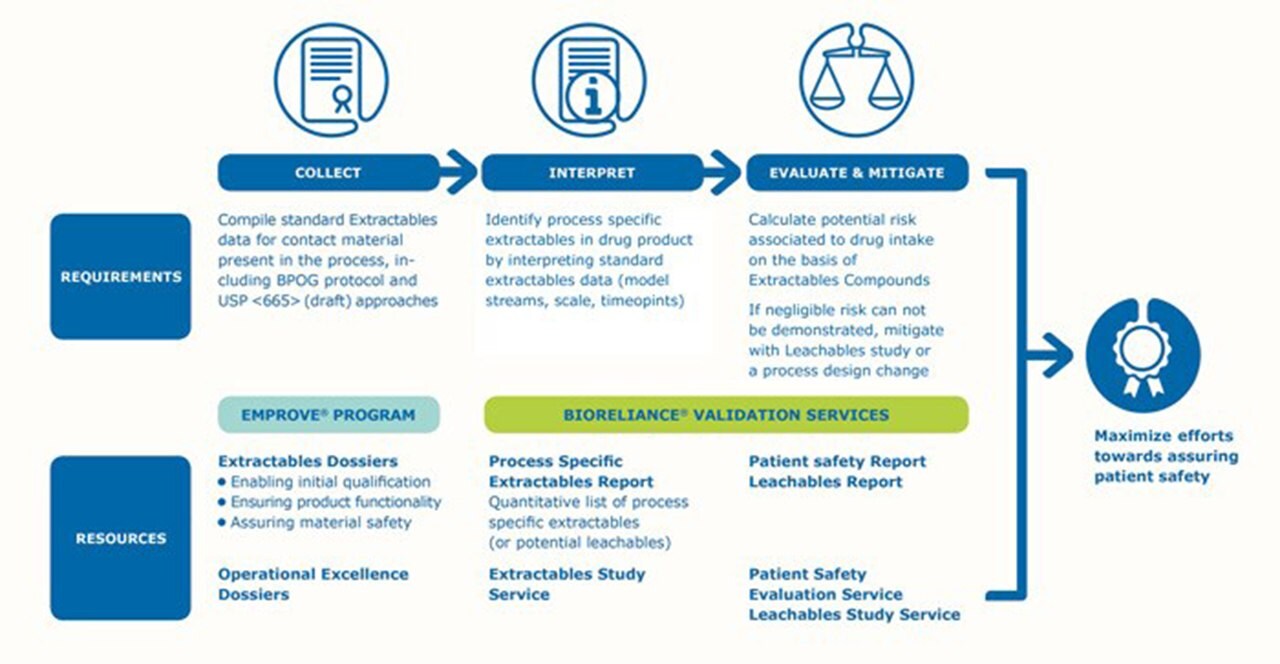

Understanding the potential of leachables to affect patient safety is a critical step in the validation strategy of any biopharmaceutical manufacturer. Our Extractables & Leachables (E&L) services will consider a risk-based approach to determine if patient safety is adversely affected by plastic materials coming into contact with the final drug product during your process, while assessing potential toxicity to patients.

In accordance with regulatory expectations, our E&L team will conduct a thorough interpretation of the extractables datasets while evaluating the criticality of your process train and single-use system. We can determine:

- Single-use components to be evaluated

- Choice of analytical method

- Model solvent(s)

- Relevant worst-case conditions

Seamless and robust E&L assessment

To demonstrate that filtration devices and single-use systems materials utilized in your manufacturing will not adversely affect a drug product’s safety for patients, we assist you in conducting a risk assessment and recommend a step-by-step validation strategy.

Extractables and Leachables (E&L) Assessment

- Extractables evaluation. By considering a worst-case and a model solvent approach, extractables data will be compiled through our analytical studies or via our Emprove® Program.

- Patient safety assessment. A patient safety evaluation is performed by an in-house toxicologist to determine the potential risk to patients. Extractables and/or leachables data, the manufacturing process, and drug posology are used to calculate the potential daily intake of potential leachables compared to exposure limits.

- Leachables testing. When required by a risk-based approach, a leachables study is conducted using end-user process conditions and products to identify compounds from the filtration device and single-use systems, followed by a patient safety assessment.

The resulting extractables or leachables data package either proves and affirms the E&L safety of your manufacturing process or establishes the need for additional evaluation. BioReliance® Validation Services can further help you mitigate risks with flushing studies and alternative process designs.

Request a quote and get started today.

Related Product Resources

To continue reading please sign in or create an account.

Don't Have An Account?