Application Note - Sterility Testing of Products with Antimicrobial Properties

Sterility testing of antibiotics and products with inhibitory properties

Some drugs are formulated with antibiotics, preservatives or other chemicals that affect microbial viability and growth. When these drugs are tested for sterility, it is necessary to eliminate their inhibitory effects. If not, the recovery of the microorganism(s) potentially present in the sample may be reduced, thereby increasing the risk of a false negative result. As described in the Pharmacopoeias, membrane filtration is the method of choice for sterility testing, whenever the nature of the products permits. To be effective against antimicrobial effects, filtration must be combined with adapted systems and appropriate procedures.

We recommend following three golden rules:

- Maximize the solubility

- Minimize the contact time with the membrane

- Optimize the rinsing.

Materials

- Steridilutor® NEO device with expansion chamber: TZVC00010

- Steridilutor® NEO device for liquid transfer Kit: TZA000010

- Red base Steritest™ NEO filtration devices: TZHVAB210 or TZHVAB205 (double packed)

Soybean–casein digest medium (SCDB), fluid thioglycollate medium (FTM), clear fluid thioglycollate medium (CTM), rinsing fluid A, fluid D, fluid K: double packaged media and fluids available; different format available. Culture media and rinsing fluids

Equipment

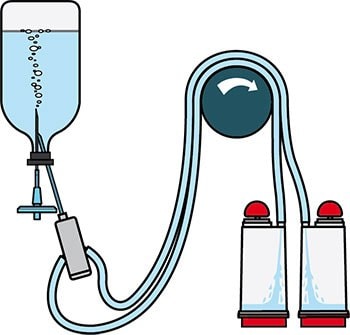

Steritest™ Symbio Pump: for laminar flow hood or isolator.

Maximize the solubility: dissolve and/or dilute the product

Pure products (solid or liquid) are difficult to rinse and residuals from products might be a major inhibitory factor in sterility testing. In the case of powders, a good dissolution is required to avoid any possible aggregate (membranes have a great affinity for aggregates). For liquid antibiotics, a dilution step is strongly recommended to reduce the concentration of the antimicrobial agent. This will reduce the possibility of binding of the agent to the filter. Specific Steritest™ NEO closed systems allow aseptic dissolution/dilution of product samples. The Steridilutor® NEO system is specifically designed to dissolve and dilute drugs in vials. The Steridilutor® NEO device for liquid transfer kit enables to dilute liquids from open ampoules into a diluent container with septum.

Minimize the contact time with the membrane

Molecules adsorb differently to a membrane depending on its polymeric structure. For testing the sterility of antibiotics or products with preservatives, USP recommends a “low binding filter material, such as polyvinylidene difluoride” (USP33, chapter <1227>). Another important aspect is the thickness of the membrane. During filtration, inhibitory residues can get trapped within the membrane. Therefore the thinner the membrane is, the lower the risk of retention will be. Steridilutor® NEO system devices for antibiotics and products with antimicrobial activity (are specifically designed for this application. The devices are made from low binding PVDF filter material (Durapore®) which has a thin membrane of about 120 to 150 μm. If multiple samples need to be filtered it is recommended to pool them before filtration. The Steridilutor® NEO system is specifically designed to pool liquid into one single container without the risk of cross contamination. Filtration of the pooled samples is then performed in one shot by using the red base Steritest™ NEO filtration device: TZHVAB210. Notice that the TZHVAB210 unit, among the red base filtration devices, is always recommended when testing antibiotics.

Optimize the rinsing: use a test device configuration that minimizes product retention

The way a closed sterility test device is assembled can also impact the risk of having false negative results. In some filtration devices available on the market, the membrane is held in place by pinching it between the edge of the filtration canister and the base of the device. This design generates “pockets” at the periphery of the membrane which collect residuals during product filtration. Removal of these residuals by rinsing is difficult and often impossible. With Steritest™ NEO devices, the membrane is thermosealed to a specific holder (base), with no generation of edge “pockets”. Trapping of product residuals is therefore prevented, optimizing rinsing efficacy.

Discover our full range of products for sterility testing on our website.

To continue reading please sign in or create an account.

Don't Have An Account?