Ultrasensitive Determination of Silicate in Process and Boiler Water

Method: Photometric determination by silicomolybdenum blue analogous to APHA 4500- SiO2 D+E and DIN 38 405-21 and ASTM D859-10

Introduction

Build-up of undesirable deposits (i.e., scale) on industrial equipment like pipes, boilers, and turbines, is a problem that must be addressed in order to maintain efficiency. One of the main causes of this type of buildup, especially at high pressure, is silicate, which is often dissolved in steam.1 To minimize the need for time-consuming cleaning operations that interrupt operations, regular silicate determination in process and boiler water is necessary. Here, we describe the ultrasensitive quantification of silicate in process and boiler water using the Spectroquant® photometric system.

Experimental Method

In sulfuric solution silicate ions react with molybdate ions to form a yellow heteropoly acid. This is reduced to silicomolybdenum blue that is determined photometrically. The method is analogous to APHA 4500-SiO2 D+E, DIN 38 405-21, and ASTM D859-16.

Reagents, Instruments and Materials

Reagents

- Spectroquant® Silicate (Silicic Acid) Test Method: photometric 0.25 - 500.0 μg/L SiO2 0.12 - 233.7 μg/L Si (1.01813)

- Ultrapur Water (1.01262)

- Sodium hydroxide solution 0.5 mol/L Titripur® (1.09138)

- Silicon standard solution traceable to SRM from NIST acidic, (NH4)2SiF6 in H2O 1000 mg/L Si Certipur® (1.12310)

Instruments

- Spectroquant® UV/VIS Spectrophotometer Prove 600 (1.73018)

Materials

- Rectangular cell 100 mm (1.74011)

- Plastic Syringes, 20 mL, Luer slip, polypropylene (XX1102012)

- Syringe filter holder Millex-GP Filter, 0.22 μm, PES 33 mm, non-sterile (SLGP033NS)

- Preparation vessels: Volumetric flasks and sample beakers, plastic

- Precision pipettes with plastic tips for 200 μL, 1000 μL, and 20 mL

Sample preparation

If the solution shows any signs of turbidity, filter the sample over the above-mentioned syringe filter holder into a clean and dry plastic vessel.

Conditioning of the working materials

If disposable plastic materials are not available (e.g., disposable syringes for piston pipettes; 50-mL centrifuge tubes), the materials should first be rinsed free of silicate with sodium hydroxide solution 0.5 mol/L and subsequently washed until pH-neutral with Ultrapur water.

Measurement procedure

Determine the SiO2 content with the above-mentioned test kit. In deviation from the instructions for use for the test kit, to enhance the precision reagents Si-1 and Si-2 are not added by dropping, but instead using a pipette. For a sample volume of 20 mL, the corresponding volumes of 200 μL of reagent Si-1 and 200 μL of reagent Si-2 and 1.00 mL of reagent Si-3 are pipetted into the sample. The measurement is carried out against a blank, prepared from Ultrapur® water and the reagents in an analogous manner. The reaction times A and B remain unchanged. After measurement, the result can be read off from the instrument.

Note:

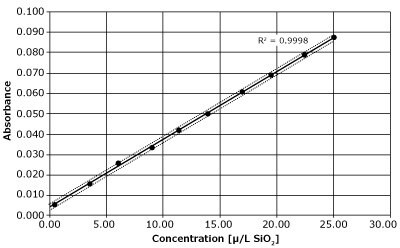

If the accuracy of the method is to be increased further, we recommend carrying out your own calibration for a limited measuring range. We recommend the performance of the calibration according to the ISO 8446-1 method. For this purpose, a user-defined method can be programmed on the Prove 600. For details see Prove Manual chapter 9.6 “User-defined Concentration Methods”. By recording a 10-point calibration curve for the measuring range 0.50 – 25.00 μg/L SiO2 the following performance characteristics could be achieved:

Figure 1.Calibration curve for the measuring range 0.50 – 25.00 μg/L SiO2 on the Prove 600

All chemicals used for the calibration are mentioned in the section “Reagents”.

References

To continue reading please sign in or create an account.

Don't Have An Account?