推荐产品

無菌

non-sterile

包裝

pack of 50

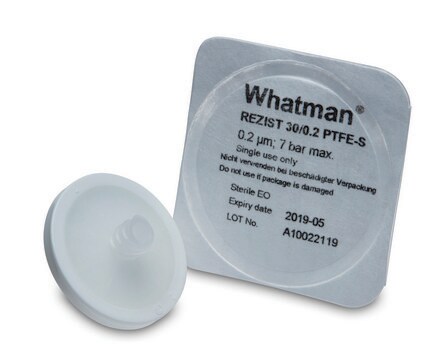

製造商/商標名

Whatman 10411211

Whatman Article No. 28415312 (US reference)

直徑

47 mm

孔徑

1 μm

適合性

suitable for (applications involving aggressive organic solvents, strong acids, and alkalis)

正在寻找类似产品? 访问 产品对比指南

一般說明

Whatman® PTFE Membranes

Whatman PTFE membranes are chemically stable and inert. They are suitable for applications involving aggressive organic solvents, strong acids, and alkalis. PTFE membranes are particularly suitable for preparing samples for HPLC analysis. The hydrophobic nature of the membrane also has applications for air and gas sterilization. The membrane is laminated onto a nonwoven polypropylene support web for improved strength and handling and can be used at temperatures up to 120ºC.

Chemically stable and inert:

PTFE is the membrane of choice for use with aggressive solvents, liquids, and gases that can attack other membranes. It is resistant to most acids, alkalis, and solvents.

Applications:

One of the major applications for the PTFE membrane is the clarification of corrosives, solvents, and aggressive fluids. This includes the important requirement in HPLC analysis for sample filtration where any solid particles can cause permanent damage to the column. The 0.5 μm pore size is normally used. Air and gas sterilization make use of the hydrophobic characteristics of PTFE membranes and their ability to stop aqueous aerosols. Usual pore sizes are 0.2 μm and 0.5 μm. Sterile venting of vacuum manifolds, fermentation vessels, and sterile filtrate tanks and containers utilize PTFE 0.2 μm membranes.

WTP and TE membrane ranges:

WTP membranes use a polypropylene grid as the support material whereas the TE range use a randomly arranged polypropylene support material.

Whatman PTFE membranes are chemically stable and inert. They are suitable for applications involving aggressive organic solvents, strong acids, and alkalis. PTFE membranes are particularly suitable for preparing samples for HPLC analysis. The hydrophobic nature of the membrane also has applications for air and gas sterilization. The membrane is laminated onto a nonwoven polypropylene support web for improved strength and handling and can be used at temperatures up to 120ºC.

Chemically stable and inert:

PTFE is the membrane of choice for use with aggressive solvents, liquids, and gases that can attack other membranes. It is resistant to most acids, alkalis, and solvents.

Applications:

One of the major applications for the PTFE membrane is the clarification of corrosives, solvents, and aggressive fluids. This includes the important requirement in HPLC analysis for sample filtration where any solid particles can cause permanent damage to the column. The 0.5 μm pore size is normally used. Air and gas sterilization make use of the hydrophobic characteristics of PTFE membranes and their ability to stop aqueous aerosols. Usual pore sizes are 0.2 μm and 0.5 μm. Sterile venting of vacuum manifolds, fermentation vessels, and sterile filtrate tanks and containers utilize PTFE 0.2 μm membranes.

WTP and TE membrane ranges:

WTP membranes use a polypropylene grid as the support material whereas the TE range use a randomly arranged polypropylene support material.

應用

Applications:

One of the major applications for the PTFE membrane is the clarification of corrosives, solvents, and aggressive fluids. This includes the important requirement in HPLC analysis for sample filtration where any solid particles can cause permanent damage to the column. The 0.5 μm pore size is normally used. Air and gas filtration use the hydrophobic characteristics of PTFE membranes and their ability to stop aqueous aerosols. Usual pore sizes are 0.2 μm and 0.5 μm. Venting of vacuum manifolds, fermentation vessels, and sterile filtrate tanks and containers utilize PTFE 0.2 μm membranes.

One of the major applications for the PTFE membrane is the clarification of corrosives, solvents, and aggressive fluids. This includes the important requirement in HPLC analysis for sample filtration where any solid particles can cause permanent damage to the column. The 0.5 μm pore size is normally used. Air and gas filtration use the hydrophobic characteristics of PTFE membranes and their ability to stop aqueous aerosols. Usual pore sizes are 0.2 μm and 0.5 μm. Venting of vacuum manifolds, fermentation vessels, and sterile filtrate tanks and containers utilize PTFE 0.2 μm membranes.

其他說明

Field of Use : For internal research use only. Products are not intended for diagnostic use or resale.

法律資訊

Whatman is a registered trademark of Cytiva

其他客户在看

我们的科学家团队拥有各种研究领域经验,包括生命科学、材料科学、化学合成、色谱、分析及许多其他领域.

联系技术服务部门