Determination of Free and Total Glycerin in B100 Biodiesel

Michael D, Buchanan, Katherine K, Stenerson, Vicki Yearick

Reporter US Vol 27.1

Introduction

In the last decade, escalating oil prices, concerns over a reliable petroleum supply, and the persistent environmental problems associated with the extraction, transport, production/refinement, and combustion of oil and its by-products have driven research into alternate fuel sources. Remarkably, this search for viable and renewable alternative fuel sources is being performed on a global scale. One such area of research is biodiesel.

What is Biodiesel?

Biodiesel is a renewable, alternative diesel fuel produced from vegetable oils, animal fats, or recycled restaurant grease. This non-toxic, biodegradable liquid fuel consists of mono-alkyl esters of long chain fatty acids (also known as fatty acid methyl esters, or FAMEs) and may be used alone or blended with petroleum-based diesel fuels. The most common process for producing biodiesel involves two steps:

- Through the transesterification reaction, triglycerides (i.e. oils or fats) are chemically reacted with an alcohol, usually methanol, in the presence of a catalyst, like sodium or potassium hydroxide, yielding fatty acid methyl esters (FAMEs) and glycerin by-product.

- The FAMEs and glycerin by-product are then separated and purified.

- The glycerin fraction is sold for use in soaps and other products.

- Biodiesel is the name given to the FAME fraction retained for use as fuel.

The resulting biodiesel contains no sulfur or fossil fuel aromatics. Biodiesel is almost 10% oxygen, making it an oxygenated fuel, which aids combustion in fuel-rich circumstances. Biodiesel can be used pure (B100 biodiesel = 100% biodiesel) or blended (for example, B20 biodiesel =20% biodiesel and 80% petroleum diesel). Before being used or blended, B100 biodiesel must be tested for contaminants that may cause problems in diesel engines. Table 1 lists these contaminants, the problem they cause, their source, and the appropriate method for testing.

The remainder of this article will focus on the analysis of B100 biodiesel for glycerin and glyceride contaminants, providing the chromatographer with several tips and tricks for performing this application.

| Contaminant | Problem | Source | Test |

|---|---|---|---|

| Glycerin | Clogs fuel systems | Incomplete separation of FAMEs and ehrcerin into two fractions | GC per ASTM D6584 or EN 14105 |

| Mono-/Diglycerides | Clogs fuel systems | Incomplete converssion of triglycerides to FAMEs | GC per ASTM D6584 or EN 14105 |

| Triglycerides | Clogs fuel systems | Not converted to FAMEs | GC per ASTM D6584 or EN 14105 |

| Methanol | Stresses engines | Remains after manufacturing | GC per EN 14110 |

| Moisture | Stresses engines: corrodes fuel systems; gelling of fuel through ice crystal formation and nucleation: and microbial growth | Remains after manufacturing or from condensation in storage tanks | Karl Fischer coulometric titration per EN 14214 or 1SO 12937 |

ASTM D6751, ASTM D6584 and EN 14105

The specifications that must be met for B100 biodiesel to be considered an acceptable fuel source are outlined in standard specification ASTM D6751, and include a maximum limit for glycerin content. The actual testing of B100 biodiesel for glycerin is outlined in methods ASTM D6584 and EN 14105. Both methods provide for the quantitative determination of free and total glycerin in B100 biodiesel by high temperature gas chromatography after silylating the sample with N-methyl-N-(trimethylsilyl) trifluoroacetamide (MSTFA).

Calibration Standards

Glycerin determination by methods D6584 and/or EN 14105 requires the use of two internal standards and multi-component calibration solutions, each containing glycerin, monoolein, diolein, and triolein, in varying concentrations. Analysts following method ASTM D6584 are required to prepare five different multi-component solutions, while those adhering to method EN 14105 must prepare only four different multi-component solutions.

Although these chemicals are readily available, the preparation can be time consuming and requires working with pyridine. Calibration standards preparation for both methods is made easier with pre-made Supelco brand multi-component, varied concentration solutions. Use of these standards saves time and reduces exposure to pyridine. Step-by-step preparation instructions are included, and were purposefully developed to be similar to those used in preparing B100 biodiesel samples. This ensures that error, due to variation in the preparation of samples vs. standards, will be minimized.

Preparation of method ASTM D6584 calibration standards involves transferring a known amount of each of our five standard solutions into separate vials along with both internal standards (butanetriol and tricaprin) and MSTFA silylation reagent. After allowing the standard mixtures 20 minutes to fully derivatize, each is diluted with n-heptane. The standards are now ready for GC analysis.

Because our method EN 14105 standard solutions already include both internal standards, preparation of method EN 14105 calibration standards simply requires transferring a known amount of each of our four standard solutions into separate vials along with MSTFA silylation reagent. After allowing the standard mixtures 20 minutes to fully derivatize, each is diluted with n-heptane. The standards are now ready for GC analysis.

Monoglyceride Stock Solution

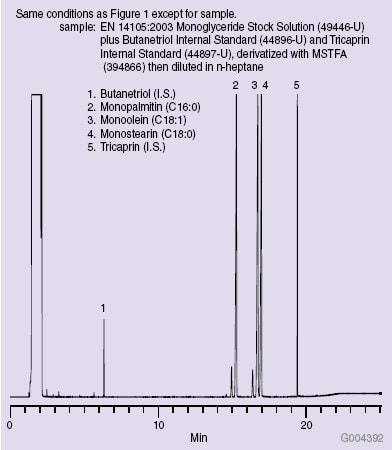

Due to the possible overlap of FAME and derivatized monoglyceride peaks in the chromatographic analysis, EN 14015 also recommends use of a monoglyceride mixture containing monopalmitin, monolein, and monostearin to aid in peak identification. Supelco offers a monoglyceride stock solution that can be used for this purpose.

Derivatization Reagents

Because of the moisture-sensitive nature of derivatization- grade MSTFA, special precautions should be taken. It is strongly recommended to purchase and use the smallest reagent package practical for the work at hand. Storing the reagent in a tightly sealed container, such as a refrigerated desiccator, will provide the best shelf life. Carefully drying all glassware and syringes that will come into contact with the MSTFA reagent during sample preparation minimizes the opportunity for the reagent to become inactive.

Storage of Derivatized Standards and Samples

To store derivatized standards and samples, blanket the vial’s headspace with dry nitrogen, tightly seal the vial, and place in a refrigerated area. Carefully stored standards have been shown to be stable for up to one week. Refrigerated standards and samples must be brought to room temperature prior to analysis.

Capillary GC Column

Cool-on-column (COC) injection beginning at 50 °C is used with these methods. Use of a heated injection port can lead to sample discrimination and is not suggested as a replacement for COC. The syringe needle used in this method must have a diameter small enough to fit inside the 0.53 mm I.D. guard column. Automated injection is highly recommended for consistency.

The Supelco MET-Biodiesel capillary GC column was designed specifically for the determination of free and total glycerin in B100 biodiesel samples. Features and benefits of this column include:

- Provides good peak shape and resolution for all glycerin/glyceride impurities of interest

- Able to separate glycerin in addition to mono- and diglycerides (as methyl esters) plus triglycerides from the FAMEs

- A maximum temperature of 380 °C (isothermal) and 430 °C (programmed) exceeds the temperature limitations specified in biodiesel methods such as ASTM D6584 and EN 14105

- Metal was selected as the column material because it holds up better than fused silica under the method conditions, virtually eliminating column breakage

- The integrated guard will protect the analytical column from excess reagent and non-volatile compounds, extending column life with a leak-free connection

- The integrated guard also acts as a retention gap, minimizing peak broadening

Four analyses, each using a different mix, were performed to illustrate the chromatographic results that can be obtained with this column. Run conditions that comply with ASTM D6584 and EN 14105 were used.

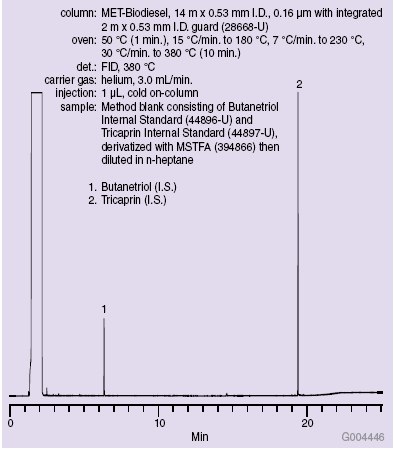

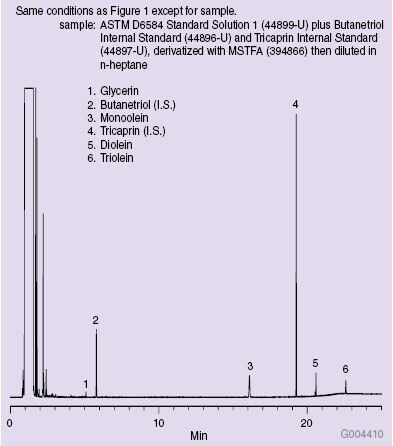

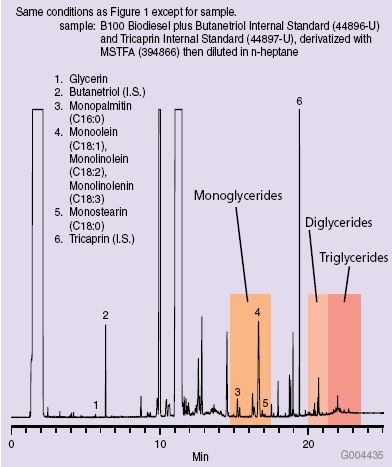

Figure 1 shows a method blank consisting of just the two internal standards. Note the stable baseline, even after an oven temperature of 380 °C is reached (at 21.81 minutes) and subsequently held. Figure 2 is of a low level ASTM D6584 calibration standard, showing good peak shape for all glycerin/glyceride analytes. Figure 3 shows good resolution of all analytes in a monoglyceride calibration standard. Figure 4 shows the analysis of a real-world B100 biodiesel sample. Note the good peak shape and resolution as well as low bleed.

Figure 1.Blank Containing Internal Standards Only on the MET-Biodiesel (28668-U)

Figure 2.ASTM D6584 Calibration Standard on the MET-Biodiesel (44899-U)

Figure 3.EN 14105 Monoglyceride Calibration Standard on the MET-Biodiesel (49446-U)

Figure 4.B100 Biodiesel Sample on the MET-Biodiesel (44896-U)

The rugged metal MET-Biodiesel column requires different care and use than fused silica columns.

To Identify the Integrated Guard:

An aluminum tab is bent over a section of the integrated guard. Tailing peaks may indicate the column is installed backward.

To Cut a Metal Column:

Score hard/saw with a ceramic wafer, grab the end to be discarded with needle-nose pliers, and then snap off.

Specialized Equipment:

For Agilent® 5890/6850/ 6890/7890 systems with a cool-on-column injector, an insert for 0.53 mm I.D. metal columns is recommended instead of an insert for 0.53 mm I.D. fused silica columns. This will help prevent damage to autosampler syringe needles.

- The insert for 0.53 mm I.D. metal columns has 4 lines on it (Agilent P/N 19245-20780)

- The insert for 0.53 mm I.D. fused silica columns has no lines on it (Agilent P/N 19245-20580)

Recommended Conditioning:

Install, establish flows, wait 15 minutes, confirm flows, and then run through the oven temperature program three times. Hold at the upper temperature 30 minutes at the end of each cycle.

Conclusion

It is hoped that the information presented here will assist analysts in their work. For further clarification of any of the information presented here or for additional questions that you may have, contact the chromatography experts in Supelco Technical Service: 800-359-3041 (US and Canada only), 814-359-3041, or techservice@sial.com

References

To continue reading please sign in or create an account.

Don't Have An Account?