Typical Procedures for Polymerizing via RAFT

Introduction

RAFT (Reversible Addition/Fragmentation Chain Transfer) is a form of living radical polymerization involving conventional free radical polymerization of a substituted monomer in the presence of a suitable chain transfer (RAFT) reagent. Use of the appropriate RAFT agent and polymerization conditions allows for the synthesis of polymers with low PDI and high functionality. For a further explanation of RAFT technology and its advantages, please read the review by researchers at CSIRO.

Reagents

RAFT Agent

- 2-Cyano-2-propyl benzodithioate (Product No. 722987)

- 4-Cyano-4-[(dodecylsulfanylthiocarbonyl)sulfanyl]pentanoic acid (Product No. 723274)

- Cyanomethyl methyl(phenyl) carbamodithioate (Product No. 723002)

- 4-Cyano-4-(phenylcarbonothioylthio) pentanoic acid (Product No. 722995)

- 2-Cyano-2-propyl dodecyl trithiocarbonate (Product No. 723037)

- 2-(Dodecylthiocarbonothioylthio)-2-methylpropionic acid (Product No. 723010)

- Cyanomethyl dodecyl trithiocarbonate (Product No. 723029)

Storage/Stability

- Product No. 723274 — Store the product at -20 °C and keep tightly closed. The product is light sensitive.

- Product Nos. 722995 and 723037 — Store the products at 2-8 °C and keep tightly closed.

- Product Nos. 722987, 723002, 723010, and 723029 — Store the products at 2-8 °C and keep tightly closed. The products are light sensitive.

Note: Please consult the Safety Data Sheet for information regarding hazards and safe handling practices.

RAFT Polymerization Procedures

- Methyl Methacrylate Polymerization: using methyl methacrylate (MMA, Product No. M55909) as the monomer, AIBN (Product No. 441090) as the initiator, and a RAFT agent (Product Nos. 722987 or 723274).

- Prepare stock solution of methyl methacrylate (15 mL, 0.14 mol) and AIBN (20.1 mg, 0.122 mmol) in 5 mL of benzene.

- Aliquot 2 mL samples of stock solution into ampules containing Product No. 722987 (12.3 mg, 0.056 mmol) or Product No. 723274 (22.5 mg, 0.056 mmol). Note: Other glassware suitable for handling air sensitive reactions, such as a Schlenk reaction tube (Product No. Z515981), may be used as an alternative to a sealed ampule.

- De-gas contents of ampules by three repeated freeze-evacuate-thaw cycles (0.05 mm Hg) and seal under vacuum.

- Polymerize by placing sealed ampule in heated oil bath (60 °C) for 15 hours.

- Vinyl Acetate Polymerization: using vinyl acetate (Product No. V1503) as the monomer, AIBN (Product No. 441090) as the initiator, and a RAFT agent (Product No. 723002).

- Prepare solution of vinyl acetate (2.0 mL, 23.23 mmol), AIBN (2.0 mg, 0.012 mmol), and Product No. 723002 (26.64 mg, 0.12 mmol) in an ampule. Note: Other glassware suitable for handling air sensitive reactions, such as a Schlenk reaction tube (Product No. Z515981), may be used as an alternative to a sealed ampule.

- De-gas contents of the ampule by three repeated freeze-evacuatethaw cycles (0.05 mm Hg) and seal under vacuum.

- Polymerize by placing sealed ampule in heated oil bath (60 °C) for 16 hours.

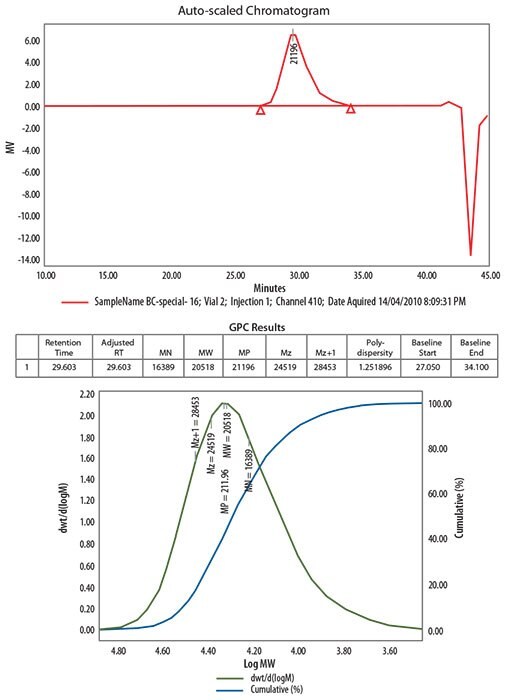

Researchers at CSIRO have tested select RAFT agents in the polymerization of vinyl acetate and analyzed the resulting polymer. The data are presented in Table 2 and Figure 1.

Figure 1.GPC analysis of poly(vinyl acetate) polymerized for 16 hours using Product No. 723002 as a RAFT agent.

RAFT agents are sold for research purposes only.

Um weiterzulesen, melden Sie sich bitte an oder erstellen ein Konto.

Sie haben kein Konto?