Considerations for Development of a Platform Lentivirus Harvest Clarification Process for Cell and Gene Therapy

New therapies and cutting-edge technologies have enabled the production of next-generation treatments that improve patient care, simplify administration and increase the availability of life changing medicines. One of the new technologies emerging in the biotech manufacturing market is the use of viral vectors for cell and gene therapy. One commonly used viral vector in this space is lentivirus, due to its robustness to package and deliver target DNA. Clarification is an important step in the manufacturing process as it impacts efficiency and subsequent downstream steps. Particle size, surface charge, as well as assay variability are among what causes difficulty when clarifying lentivirus harvest and significant losses in post-clarification virus titer yield and potentially low capacity can be observed. This work explores a variety of lentivirus harvest clarification options and items for consideration during manufacturing platform development of viral therapy production using suspension cell lines.

Introduction

Clarification is an important step in purification process development of gene therapy products using lentivirus technology, especially in a suspension cell line, where turbidity reduction and yield is essential to the success of the purification process. Typical clarification depth filters utilize diatomaceous earth (DE) and cellulose with a charged binding resin to capture charged impurities and larger sized particles within the depth filtration media. Therefore they can capture lentiviruses. In addition, pore size of filters need to be taken into consideration to avoid virus retention.

Methods

Using the Pmax™ method, constant flow rate technique (Figure 1), multiple batches of lentivirus harvest were tested during selection of a primary clarification filter. Several filter chemistries were evaluated, including Polygard® CN50 (SN50A47FF3) and CN1H (SN1HA47FF3) filters. However, the Polygard® filters were not further selected due to low capacity and high turbidity, although yield was sufficient.

Figure 1.Pmax™ experimental set-up

Millistak+® D0HC filter was included as a baseline device, Clarisolve® 60HX filters and Millistak+® CE35 filters were selected as the preferred candidates and an experiment was designed to compare the filters and confirm the initial tested results. A Clarisolve® 60HX filter flux excursion was conducted to determine increased flux effect on yield, turbidity and throughput.

For the flux excursion experiment, a single batch of lentivirus harvest was collected from the bioreactor for clarification. Primary clarification was done first in triplicate, comparing the selected filters to demonstrate repeatability, primarily with regards to yield. A separate experiment was conducted comparing primary and secondary clarification, where each train consisted of its own primary clarification and secondary clarification filter.

Results

Primary Clarification

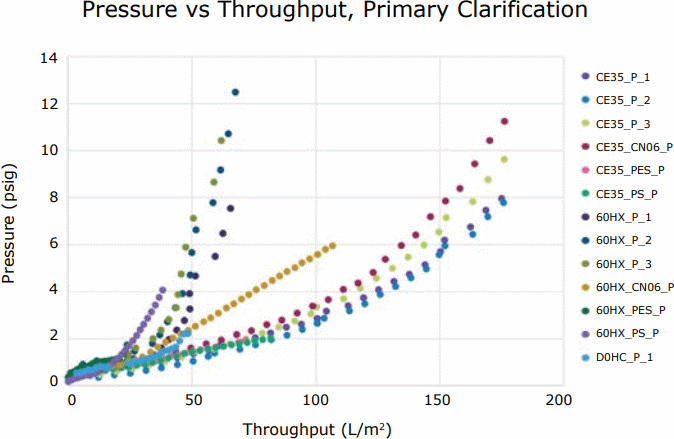

Millistak+® D0HC filter clarification resulted in low yields, removing the filter media as a feasible clarification option. Clarisolve® 60HX devices and Millistak+® CE35 devices both offer reasonable solutions for clarification, with relatively repeatable yields as confirmed by testing the filters in triplicate. The Clarisolve® 60HX device offers significant turbidity reduction and high yield and could be reasonable to use as the only clarification filter. The performance of this filter can vary with harvest characteristics. When filtering with the Millistak+® CE35 device, the yield was high, however it achieved lower turbidity reduction. Further characterization of the breakthrough profile across the Millistak+® CE35 filter will allow the user to determine if lower throughput would avoid particulate breakthrough.

It is unclear why different capacity was seen across the primary filter in the Clarisolve® 60HX device into the Polygard® CN06 filter train.

Figure 3.Pressure vs. throughput of leading primary clarification options

Secondary Clarification

This second step was conducted following both primary filters. While the throughput and yield across the Polygard® CN06 device was relatively high following either clarification filter, there was no turbidity reduction, indicating that the membrane was not adding any benefit to the clarification train. Polysep™ II and Milligard® PES devices offer differing turbidity reduction and yield, depending on the primary clarification filter. Further characterization of the end user’s process is required.

The Milligard® PES SMP device achieved 470 L/m2 and Polysep™ II CGW6 device achieved 540 L/m2 throughput when following a Millistak+® CE35 filter (Figure 5). Although the yield was relatively high across the Polygard® CN06 filters, the minimal increase in pressure drop and lack of turbidity reduction across the filters appears to indicate that the filter does not provide any benefit to clarification.

Figure 4.Pressure vs. throughput of secondary clarification options, following primary clarification

Flux Excursion

While the yield increased with increased flux, turbidity reduction and throughput were limited. As expected, the Millistak+® D0HC device yield was significantly lower than Clarisolve® 60HX devices and Millistak+® CE35 devices. (Figure 5).

Figure 5.Throughput vs. yield, final pool turbidity and final pressure of tested filtration options

Conclusions

Lentivirus technology characteristics preclude the use of typical clarification filtration options, as the product yield is unfeasibly low in these filtration trains. This work provides guidance on selecting a clarification filter using products currently in the market. Based on volumetric throughput, product yield, filtrate turbidity reduction and final pressure, this study identified two feasible primary clarification filter options, Clarisolve® 60HX devices and Millistak+® CE35 devices. Additional work is required to determine if either device can be installed as a standalone filter. In addition, this study identified two potential secondary clarification filter options, Polysep™ II devices and Milligard® PES 1.2/0.8 devices. It is important to remember that lentivirus clarification results can vary significantly, therefore these options provide the PD Scientist with a decent starting point for clarification, which can be tailored to their individual process.

To continue reading please sign in or create an account.

Don't Have An Account?